We’ve all been there. You brake a little too hard, and the sound of your groceries sliding across your truck bed fills the cab. It’s a classic truck owner problem: that wide-open space is great for big stuff but a nightmare for smaller items.

This is where pickup truck bed dividers come in. They are the simple, effective fix for that cargo chaos.

Taming Chaos in Your Truck Bed

A bed divider is an instant organization system. It carves up that sprawling, empty space into secure, manageable zones. This one addition stops gear from sliding, shifting, and smashing into itself.

The demand for this practical upgrade is huge. The U.S. truck bed accessories market was recently valued at USD 2.56 billion, and it’s expected to grow. You can get more details on market trends in recent industry reports.

Why Organization Matters

Organizing your truck bed is about safety and efficiency, not just looks. Without a divider, a sudden stop can send a heavy toolbox crashing into your cab. Lighter items can be whipped around by the wind or tumble into a corner.

By creating dedicated zones for your gear, you drastically reduce the risk of damage and make loading and unloading faster. It’s about working smarter with the space you have.

Dividers are a great starting point for a complete cargo system. To see how they fit into the bigger picture, see our guide on total truck bed cargo management. A well-planned setup ensures every piece of equipment has its own secure spot.

Exploring Different Bed Divider Types

Not all pickup truck bed dividers are the same. Understanding the main categories helps you find a solution that fits your truck and lifestyle. From simple bars to full track systems, each type has its own strengths.

The most basic option is a cargo bar. It uses tension to brace against the sides of your truck bed, creating a simple barrier. It’s perfect for keeping groceries, a cooler, or a few small boxes from sliding.

For more security, you can step up to a fixed divider. These are tough panels that drop into pre-molded slots in the truck bed, like those in Ford’s FlexBed

system. They create a semi-permanent wall for heavier gear like toolboxes.

The Power of Adjustability

If you need maximum versatility, the adjustable divider is the best choice. These dividers glide along a rail or track system installed in the bed. This setup lets you slide the barrier forward or back, resizing your cargo zones as needed.

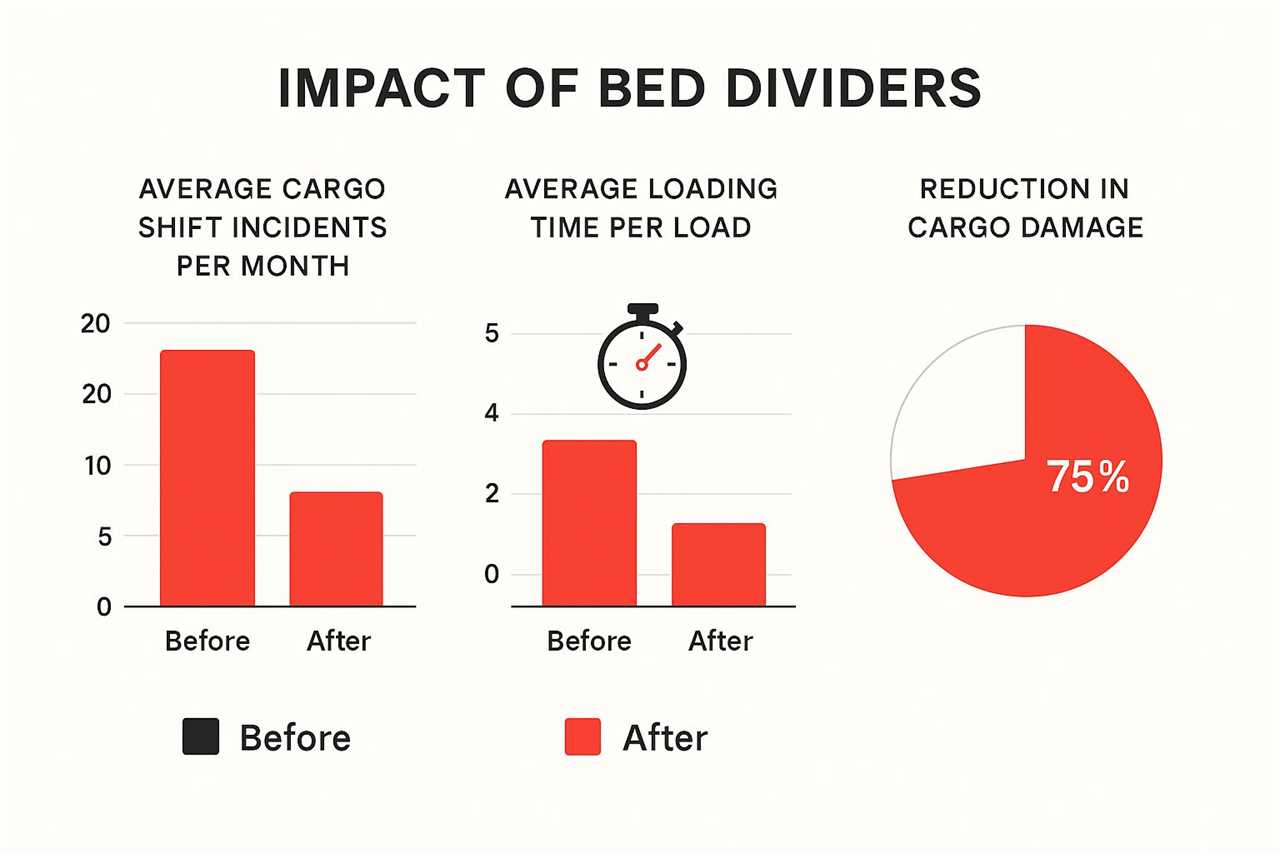

This image shows how much difference a good divider system makes in keeping gear safe and organized.

The proof is clear—dividers cut down on cargo shifting incidents and make loading faster. The key is matching the right type of divider to what you haul every day.

We’ve put together a quick comparison of the most common divider types. This table breaks down what each is best for, its adjustability, and the typical installation.

Comparing Bed Divider Options

| Divider Type |

Best For |

Adjustability Level |

Typical Installation |

| Cargo Bar |

Light-duty tasks like groceries, luggage, and small coolers. |

High – Can be placed anywhere along the bed length. |

Minimal – No tools needed; just twist to tighten. |

| Fixed Panel |

Securing specific, consistently-sized items like toolboxes or tanks. |

Low – Only fits in manufacturer-designated slots. |

Minimal – Drops into existing slots; no tools required. |

| Adjustable System |

Hauling a wide variety of gear; offers maximum flexibility. |

Very High – Slides along a track for infinite positioning. |

Moderate – Requires installing a rail or track system. |

Each of these has a place, but the “best” one depends on how you use your truck. A simple cargo bar might be all you need, while a full adjustable system is a game-changer for contractors.

Choosing the Right Material for Your Needs

A divider’s material dictates its durability, weight, and weather resistance. Think of it like picking the right tool for a job. You shouldn’t pick a material that doesn’t match what you haul.

The big three materials are high-density plastic, aluminum, and steel. Each one balances strength, weight, and convenience differently. Understanding these differences is key to finding a divider that won’t let you down.

Plastic and Composites

For everyday runs, high-density plastics and composites are fantastic. They are lightweight, won’t rust or corrode, and are usually easier on the wallet. They are perfect for groceries, sports equipment, or camping gear.

Key Takeaway: Plastic dividers give you a great mix of function and value for light-to-medium-duty hauling. This makes them a go-to choice for the average truck owner.

Aluminum and Steel

When your loads get serious, look at metal. Aluminum is a great middle-ground, offering impressive strength while staying light. It’s a versatile workhorse for securing heavier cargo.

For the toughest jobs, steel is the undisputed champ. It delivers maximum strength and impact resistance. This makes it the top pick for heavy commercial use.

Deciding between them often depends on your other gear. If you are building a heavy-duty setup, you should know how to pick a truck bed tool box that complements your divider. The push for tougher materials is a major industry trend; you can discover more insights about truck accessory trends to learn more.

How to Ensure a Perfect Fit for Your Truck

A truck bed divider that doesn’t fit right is useless. It can’t do its job, leaving you with a rattling piece of gear in your bed. To avoid that frustration, you must get the fit right.

This boils down to understanding the difference between universal and model-specific dividers. A model-specific divider is engineered for your truck’s exact specs. A universal-fit product, like a tension cargo bar, offers more flexibility but a less secure feel.

Taking Accurate Measurements

Before you buy, grab a tape measure. You need two key measurements to ensure a divider will work. Don’t just guess based on your bed length; the internal dimensions matter most.

- Interior Width: Measure from one side wall of the bed to the other at the narrowest point, usually between the wheel wells.

- Interior Length: Measure from the inside of the bulkhead back to the inside of your closed tailgate.

Important Note: Always double-check the divider manufacturer’s specs. They will list the exact dimensions their product fits or the specific truck models it’s made for.

Accounting for Other Accessories

Your current setup can cause problems if you are not careful. Things like bed liners and tonneau covers must be factored in. A thick, drop-in plastic bed liner, for example, will reduce the interior width.

Likewise, many tonneau covers use clamps or rails that mount along the inside of the bed walls. This is exactly where some dividers need to attach. Always check compatibility notes from both manufacturers.

A Guide to Divider Installation

So you have picked a divider. How much work is it to get it in your truck bed? The answer ranges from a five-minute task to a project requiring power tools.

Knowing what you’re getting into ahead of time is key. Some people love a DIY project, while others want to get it in and start loading.

Tension-based cargo bars are as easy as it gets. You just twist or ratchet the bar until it’s snug. The same goes for panel-style dividers made to drop into pre-molded slots on many modern trucks.

This plug-and-play approach is becoming more common as manufacturers make products more user-friendly. You can read more about this trend in the truck accessories market if you’re interested.

Installation Types Explained

Let’s break down the common installation methods.

- No-Tool Installation: This is the easiest category. It includes tension rods and drop-in panel dividers. They are designed for instant use.

- Minimal-Tool Installation: Many adjustable systems land here. You’ll likely need a basic wrench or screwdriver to attach clamps or small brackets.

- Drilling Required: This is for heavy-duty dividers that must be bolted directly into the truck bed. This ensures they can handle serious weight.

Pro Tip: Before installing, give your truck bed a good cleaning. A clean surface means a better fit. It also stops dirt from getting wedged under contact points, which can scratch your bed.

A good divider is often just one piece of a system. To create a complete setup, look at our guide to truck bed organization systems. It will help you see how your divider can work with other gear.

Common Questions About Bed Dividers

You have seen the types, materials, and installation methods. But you probably still have a few questions. Let’s clear up some of the most common things people ask.

Can I Use a Bed Divider with a Tonneau Cover?

Yes, you almost always can, but compatibility is key. You must check the details for both your tonneau cover and the divider.

Most divider makers design their products to work with covers. This is especially true for dividers that mount to the bed floor or use a tension rod.

Low-profile dividers that sit below the bed rails are a safe bet. The main thing to watch for is interference where the cover and divider mount.

As a rule, look for dividers that use factory tie-down points or a track system on the bed floor. These designs almost never get in the way of tonneau cover hardware.

Are Universal Bed Dividers a Good Option?

For light-duty jobs, universal dividers like tension bars are a great, budget-friendly choice. They’re perfect for stopping grocery bags from sliding around. You can install or remove them in seconds.

For anything heavy or bulky, a universal bar is not strong enough. For serious gear, you need a model-specific system built for your truck’s exact dimensions. That is the only way to get a truly secure fit.

Ready to take control of your cargo and find the perfect accessories for your rig? Explore expert guides and gear reviews at Offroading.com to outfit your truck for any adventure. Learn more at Offroading.com.

https://offroading.com/pickup-truck-bed-dividers/?utm_source=rss&utm_medium=rss&utm_campaign=pickup-truck-bed-dividers

Backyard GrillingWeekend WarriorsAdvice from DadBeard GroomingTV Shows for Guys4x4 Off-Road CarsMens FashionSports NewsAncient Archeology World NewsPrivacy PolicyTerms And Conditions

Backyard GrillingWeekend WarriorsAdvice from DadBeard GroomingTV Shows for Guys4x4 Off-Road CarsMens FashionSports NewsAncient Archeology World NewsPrivacy PolicyTerms And Conditions