Rounds built upon the principals of Modern Cartridge Design dominate in long-range rifle competition because they deliver better precision than the classics can. John B. Snow

Modern Cartridge Design is a series of tenants that guide how firearms and ammunition engineers have created most of the centerfire rifle rounds unveiled in recent years. This philosophy is one of the major drivers behind the accuracy gains in today’s rifles, whether we’re talking about custom rigs with eye-popping price tags or budget guns you can pick up at a big-box store.

Cartridges that Embody Modern Cartridge Design

- Are optimized for aero-ballistically efficient, heavy-for-caliber, high BC bullets

- Use faster twist rates to stabilize those projectiles

- Propel those bullets at relatively moderate velocities

- Have cases with adequate neck length to support these projectiles

- Can seat these bullets to specified cartridge length without impinging on the powder column

- Employ minimal body taper

- Headspace off sharp shoulders

- Have snug throats with a standardized leade geometry

While not every cartridge unveiled in the last decade or two adheres to all these points, many do. And any round meant for precision shooting and long-range hunting checks all—or nearly all—these boxes.

Good examples of cartridges following the Modern Cartridge Design (MCD) blueprint include: 6.5×47 Lapua, the 6mm and 6.5mm Creedmoor, the PRC family (6.5 PRC, 7 PRC, .300 PRC), 6.8 Western, 6mm GT, and 6mm Dasher.

Old versus new. The 6mm Creedmoor (right) incorporates many design improvements over the .243 Win. John B. Snow

Why Modern Cartridge Design Works

Maybe the best way to think about MCD is that it employs a number of best practices—many of them derived from benchrest competition–to tip the odds in the cartridge’s favor. Individually, each of these tenants might not move the needle very much in terms of performance, but combined together they result in cartridges that have set new benchmarks in terms of accuracy and practical performance in long-range competition and in the field.

Cartridge Alignment

One key to accuracy is consistency. The straighter you can align a cartridge in a barrel’s chamber, the better. This is the reason MCD cartridges minimize body taper, and headspace off sharp shoulders. Both help the cartridge to sit centered in the chamber and parallel to the bore.

In the past, many rifle cartridges were designed with significant taper and shallow shoulder angles to help them feed and extract smoothly.

This approach is particularly evident with rounds like the .30/30, but you also see it with the .30/06 and .308 Winchester, which incorporated body taper and shallower shoulder angles to work better in the semi-auto and fully automatic weapons of the day. And, of course, both the .308 and ought-six spawned numerous cartridges that exhibit those traits too.

With lots of taper and shallow shoulders on a cartridge you’re more prone to getting tolerance slop and a case that doesn’t lie perfectly in the chamber.

The steep shoulders found in MCD (30 degrees or more) also help establish precise, consistent headspace, which is the distance from the bolt face and the point of contact between the case and the chamber. (For cases that headspace off the shoulder, the distance is usually measured from the midpoint of the shoulder.) Cartridges that headspace off a shallow shoulder like the .30/06 (17.5 degrees) and .308 Win. (20 degrees) are not as easy to get to headspace exactly. The same is true with belted cartridges like the 7mm Rem. Mag. and .300 Win. Mag. that headspace off a raised rim at the base the case. (Though, in recognition of this shortcoming, some modern chambers for these magnums are cut so the round headspaces off the shoulder.)

Sharper shoulders also benefit handloaders, as the cases won’t stretch as quickly reducing the need for case trimming.

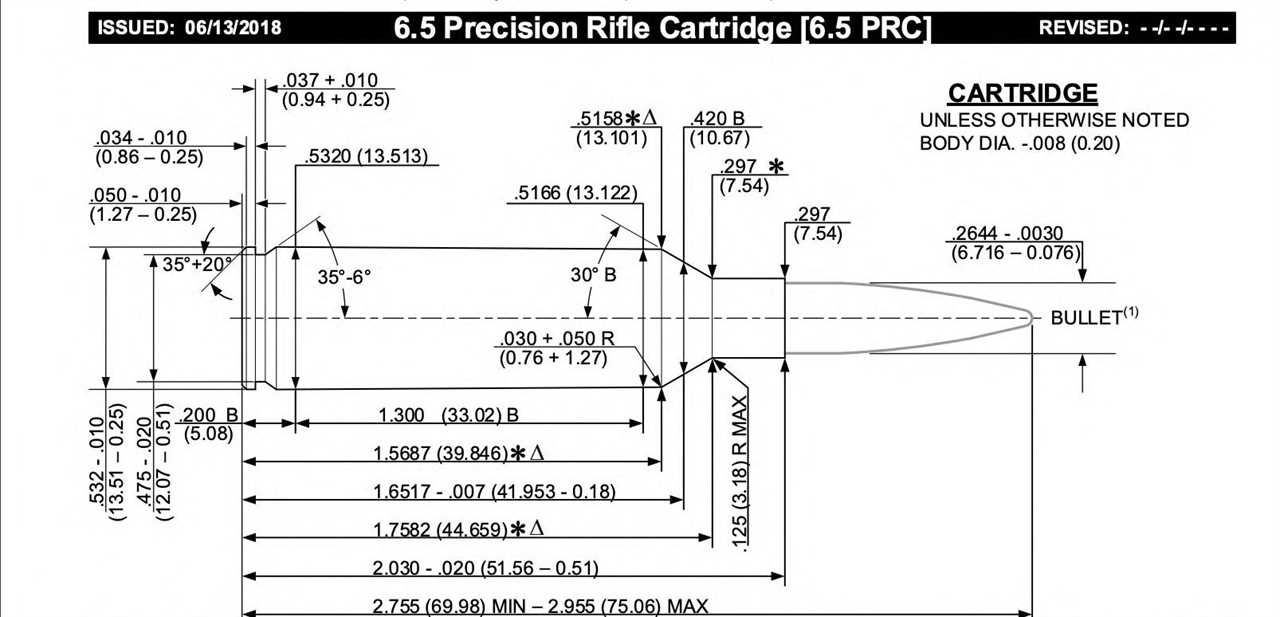

The 6.5 PRC incorporates all the elements of MCD. Courtesy of SAAMI

Interior Ballistics

The chain of events that occurs when shooting a rifle is surprisingly complex. Rather than detail the whole process, we’ll pick things up as the firing pin strikes the primer and talk about how it relates to Modern Cartridge Design.

When the primer touches off it sends a jet of hot slag into the propellant bed that ignites the powder. The gasses released by the powder are what push the bullet out of the case and into the barrel.

For peak accuracy we want this event to be as consistent as possible. If the base of our bullet extends past the cartridge neck and into the body of the case a couple unfavorable things can occur. One, the base of the bullet can be pushed sideways as the gasses expand causing it to enter the rifling at a tilt. And once it starts in the rifling at a tilt, it remains tilted as it spirals down the bore. There’s even evidence suggesting a bullet can be bent if enough of it protrudes below the juncture where the case neck and body meet. Needless to say, neither scenario is conducive to accuracy.

This becomes an issue when trying to load long, high BC bullets in cases designed to drive lighter bullets as fast as possible by maximizing powder capacity. In order for the cartridge to fit in the magazine and in the chamber, these high BC bullets need to be seated far back with a portion of the bullet in the powder chamber.

Take the 28 Nosler, for instance. This 7mm behemoth introduced in 2016 does a good job with 150- to 160-grain bullets, spitting them out around 3300 fps. But with bullets weighing 175 grains or more you run into the issue described above. Shooters either need to throat out their chambers to accommodate the longer bullets (and possibly end up needing to single-load the rounds) or seat these bullets way back in the case. This design shortcoming is one reason you don’t see the 28 Nosler used in long-range competition in any meaningful numbers.

The other problem with seating these long sleek bullets far back in the case is that the neck might not grip the bullet in the best place. The bearing surface on these bullets might not be fully supported within the case neck, which also isn’t ideal.

This is why the 7mm PRC, for instance, has a notably shorter body than the 28 Nosler—so that it can use bullets like the 175-grain ELD-X and ABLR, the 180-grain ELD-M, the 190-grain A-Tip, and the 195-grain Berger EOL, and seat them correctly so they are supported by the case neck and don’t have the base of the bullet extending into the case body.

The 6.8 Western, an MCD cartridge which uses a .277-in. caliber bullet, has already gained a large following. John Whipple

Short, Fat Efficiency

We’ve also learned that short, fat cases—which really gained traction with the rollout of the short mags in the early 2000s by Winchester and Remington—are very efficient. If you take a long-skinny case and a short-fat case with the same volume, the short-fat case will deliver faster muzzle velocities with the same powder charge.

This is another reason MCD cartridges are thicker around the middle in proportion to their length than vintage case designs.

Modern Cartridge Design Throat Geometry

One small but significant tweak in the evolution of cartridge design is throat geometry. (The throat is the unrifled section of the bore that surrounds the bullet in the chamber.) MCD cartridges have throats that are just barely larger than the bullet diameter. This promotes good alignment between the bullet and bore as the projectile enters the rifling—helping ensure that the bullet is straight as it begins its journey down the barrel.

Many older cartridges have throats significantly larger than the bullet diameter, and that slop can cause accuracy issues.

The success of the 6.5 Creedmoor ushered in the broad acceptance of modern cartridge design. John B. Snow

Putting some numbers to this, MCD cartridges spec their throat diameters at less than .001 inch over bullet diameter, often .0005 to .0006 inches—so half a thousandth of an inch or so. This includes the 6mm Creedmoor (.0005 in.), 6.5 Creedmoor (.0005 in.), 6.5 PRC (.0005 in.), 6.5-284 Norma (.0006 in.), 6mm GT (.0006 in.), 7 PRC (.0006 in.), .300 Norma Mag. (.0007 in.), and .300 PRC (.0008 in).

Contrast that with the SAMMI spec throats for these cartridges: .243 Win. (.0033 in.), .264 Win. Mag. (.004 in.), 6.5×55 Swede (.0053 in.), .308 Win. (.002 in.), .30/06 (.0026 in.), and .300 Win Mag. (.007 in.) Comparatively, putting a bullet down these throats is like throwing a hotdog down a hallway. Of course, you can get custom reamers for these old cartridges to make barrels with tighter throats—and can lengthen the throats to seat longer bullets and use faster twist rates on the rifling to make them more MCD-like. But that does involve a lot of effort and can lead to other issues, such as difficulty getting the rounds to fit in the magazines they were originally designed for.

Standardized Leade Angle

The leade is the where the throat transitions into the rifling and is machined at an angle. The standard with MCD cartridges is 1.5 degrees with a couple exceptions. This is also expressed as 1° 30¢ (one degree, thirty minutes, since there are 60 minutes in a degree).

Many older cartridges have the same 1.5-degree leade angle, such as the .243 Win., while others are steeper (7mm Rem. Mag., 3 degrees) and others are shallower (.30/06, 1° 22¢).

How much of a difference leade angle makes in terms of measurable precision is debatable. But it is worth noting, since the 1.5-degree leade has become nearly universal with MCD rounds.

The PRC family (from left)—6.5 PRC, 7mm PRC, .300 PRC—are MCD cartridges that excel in open-country hunting and long-range competition. John B. Snow

High BC Bullets

Whether talking about big-game hunting or long-range target shooting, we’ve seen a marked shift toward bullets that are longer, sleeker, and generally heavier than those used in the past.

These bullets are defined by their high ballistic coefficients (BCs) which make them incredibly efficient downrange. Though they might not start at the same blistering velocities as the lighter bullets used in traditional magnum rounds, they often catch up to those projectiles downrange because they do a better job retaining their speed.

This also makes these bullets more wind resistant than the lighter, faster bullets, which is a huge advantage when shooting under practical field conditions.

Take, for instance, my Allterra Arms 6.5 PRC that shoots Hornady 143-grain ELD-X bullets at 2950 fps. Even though this lighter bullet starts at the same speed as a 180-grain Nosler Accubond from a .300 Win. Mag.—and therefore has a much lower muzzle energy—by the time you get to 600 yards the 143 ELD-X has dropped 65 inches versus 76 inches for the 180-grain bullet. More impressive, the retained velocity and energy on the 143 ELD-X at 600 yards (2202 fps / 1539 ft-lb) is better than the 180-grainer (1937 fps / 1500 ft-lb). Go to 800 yards, and the 6.5 PRC has left the .300 Win. Mag. in the dust: 143-grain drop, velocity, and energy (137 in. / 1967 fps / 1229 ft-lb) versus the 180-grainer (163 inches / 1656 fps / 1096 ft-lb).

Best of all, you get this downrange performance at a fraction of the recoil, which is why both bullet size (meaning caliber diameter) and muzzle velocity aren’t the best way to gauge cartridge performance.

The author with a tight 3-shot group at 1200-yards made possible by high BC 110-grain Hornady A-Tips from a 6mm Creedmoor. John B. Snow

Faster Twist Rates

To stabilize these high BC bullets, MCD cartridges are spec-ed with fast twist rates. Whereas the .243 Win. has a factory 1:10 twist, the 6mm Creed and 6mm GT have 1:7.5 twists to stabilize bullets up to 115-grains. In the 6.5mms the difference is less pronounced. The .264 Win. comes with a 1:9 twist (as does the 6.5-284 Norma), while the 6.5 Creed, 6.5 PRC, and the majority of 6.5×55 Swedes are 1:8.

The 7mm Rem. Mag. has a 1:9.5 twist while the 7 PRC is a 1:8. The old .30-cals, like the .30/06 and .300 Win. Mag. and most .308s are 1:10, while the .300 PRC is a 1:8.5 and the .300 Norma Mag. is a 1:9.2.

Running a faster twist rate allows for a cartridge to use a wider variety of high BC bullets. It can also mean the difference between a given bullet working well in one cartridge/twist combination, while delivering poor results in another.

A potential downside to faster twist rates is that some older bullet designs can be stressed when spun too fast. That can lead to poor terminal performance and in extreme cases have the bullet come apart in flight, especially when shot at high muzzle velocities.

Velocity as Performance Fallacy

For the longest time shooters and hunters have worshiped at the altar of velocity. It was the main—and often only—yardstick by which we measured cartridge performance before the arrival of today’s aero-ballistically efficient high BC bullets.

Faster equaled better. So, if a .308 Win. shooting a 165-grain bullet at 2680 fps didn’t blow your hair back, you could send it out of a .30/06 at 2800 fps, or a .300 Win. Mag. at 3100 fps, or a .300 Weatherby Mag. at 3350 fps, or a .300 Rem. Ultra Mag. at 3400 fps. But does the .300 RUM really “outperform” the .308 Winchester? Rifle and ammunition sales don’t support that assertion, but many hunters and shooters still revert to this mindset when debating the merits of old cartridges versus the new.

This attitude has its origins in the pre-laser rangefinder era of hunting and shooting, where hunters often had to guesstimate ranges to their targets. A cartridge that shot a light or medium weight bullet really fast was helpful for shooting to 300 or 400 yards since at those ranges they were pretty forgiving with range estimation.

Many hunters still think this way and insist their classic cartridge outperforms MCD cartridges based on muzzle velocity alone. By this logic, the best racecar in the world is a top fuel dragster since nothing is faster—but anyone with a lick of sense knows there’s more to performance than velocity, whether we’re talking cars or cartridges. Handling, recoil, consistency, wind forgiveness, retained downrange performance, and precision all matter too—and this is where Modern Cartridge Design has the edge.

These classic .30 cals aren’t going away—but if they didn’t exist, none of them would be designed the way they are today. John B. Snow

We Don’t Make ’Em Like We Used To

Bring up the oh-so-trendy 6.5 Creedmoor, for instance, and you’ll trigger the 6.5×55 Swede and .264 Win. Mag. fans who will make the velocity-is-king argument. It’s like dangling a worm on a hook in a pond full of ravenous bluegills. They can’t help but take the bait.

Now don’t get me wrong. The Swede and the old .264 are both fine rounds and more than capable for most hunting and shooting tasks. But if neither existed no one would design them today. The same holds true for all our legacy cartridges. If we were starting from scratch with what we know about cartridge design, we’d never end up with the .30/06, .270 Win., 7mm Rem. Mag., .300 Win. Mag. or any other of our iconic cartridges.

Just like there’s no comparing earlier generation Ford F-150s to those built today, it is silly to say the old cartridges are as good or better than what we’re making now. We know a lot more about how to build good trucks and cartridges in the 2020s than we did in the 1950s (or 60s or 70s).

And as important, through the revolution in CNC machining we’re able to hold actions, barrels, bullets, brass, and ammunition to tighter tolerances than gun and ammo makers a generation or two ago could even dream about. These advancements make the tenants of Modern Cartridge Design achievable in a way they weren’t in decades past.

The Value of Moderate Velocities

When it comes to muzzle velocity it’s easy to have too much of a good thing. The example above comparing the 165-grain bullet from a .308 Win. (2680 fps) to a .300 RUM (3400 fps) illustrates the point. The historic accuracy of the .308 Win. is well known. No one has ever accused the .300 RUM of that quality. The recoil and muzzle blast generated by the RUM compounded with the challenges of getting a cartridge designed for speed-at-all-costs to shoot consistently makes it a non-starter in the precision conversation. (To say nothing of its old-school 1:10 twist, which precludes it from using some of the most effective high BC .30-caliber match bullets.)

We’ve learned that there’s a sweet spot when it comes to muzzle velocity (MV) as it relates to precision. When we drive high BC match and hunting bullets in MCD cartridges somewhere between 2700 and 3050 fps, really good things happen downrange.

Not only do we get consistently tight groups, whether we measure them at 100 yards or 600, we also get consistent muzzle velocities, represented by small shot-to-shot standard deviations (SDs) and extreme spreads (ESs).

Controlling the Waterline

The reason we care about low SDs and ESs is that it helps us control bullet drop at longer ranges. When we plug data into ballistic calculators, we use a specific muzzle velocity and the closer to that muzzle velocity our shots are in the real world, the better that calculation will be. When our MVs are consistent, we say the rifle and load have a good waterline, meaning our elevation corrections at longer ranges will be spot on.

For shooting at moderate distances, say within 600 yards, we can tolerate a fair bit of variation in MV from shot to shot. But beyond that inconsistent MVs can turn hits into misses.

Improved Marksmanship

Moderate MVs also equate to moderate recoil. The benefits of a round with moderate recoil when it comes to marksmanship are difficult to overstate. They help the shooter maintain correct form, improve the ability to call shots—which is one of the most critical skills for any rifleman to develop—and all things being equal, rounds that generate less recoil are inherently more accurate than hard-kicking cartridges.

The long and heavy high BC hunting bullets used in Modern Cartridge Design—such as the 143-grain ELD-X the author used on this bull in Montana—are deadly on all manner of big game. John B. Snow

What About Killing Power?

Terminal ballistics is often misunderstood, in large part because when a bullet strikes an animal it is an inherently chaotic act that doesn’t lend itself to black-and-white conclusions. Velocity certainly plays a role in how effective a round is on game, but more important is bullet selection and shot placement.

Every hunting bullet out there has a performance envelope defined by its minimum and maximum impact velocities. If it hits the target going too slowly (such as at extreme ranges) it might fail to mushroom and pencil through. If it hits it going too fast, the bullet can grenade on contact, leaving a horrible surface wound that fails to reach the animal’s vitals.

But when used within its performance envelope—and placed properly on the animal—a quality hunting bullet will upset and penetrate deeply, damaging tissue and resulting in a quick, ethical kill.

Historically, hunters liked to point to kinetic energy as a proxy for terminal ballistics. How many times have we heard that a big-game animal like a deer “requires” 1,000 ft.-lb. of energy for a clean kill? While kinetic energy plays a role with terminal results, this emphasis is misguided.

A better way to think about terminal ballistics is as the interplay among bullet design, impact velocity, and density of the target media.

We’re blessed to live in an era with a multitude of excellent hunting projectiles. And some of the most impressive bullets are the high BC bullets found in MCD cartridges. Good examples include Nosler’s Accubond Long Range, Hornady’s ELD-X, and Federal’s Terminal Ascent.

Final Thoughts on Modern Cartridge Design

There’s a lot of misinformation about MCD cartridges. The detractors dislike them because they feel they’re overhyped and “don’t do anything better” than older designs. While they have a point about the hype—some of the exhortations by their fanboys is over the top—the second point is just wrong.

MCD cartridges do plenty of things better than older designs. All you have to do is look at what’s being used in—and winning—hunting-style and other long-range competitions. MCD rounds dominate.

When it comes to how effective MCD versus old-school rounds are when hunting, the case is less clear cut. For the majority of big-game hunting, our older traditional cartridges work just as well as the newest rounds being trotted out, and vice versa. MCD cartridges are just as effective as the older rounds.

That said, there are scenarios where the inherent accuracy, improved shootability, and superior downrange performance of MCD cartridges outstrips what can be achieved with older designs. Whether that is relevant or desirable to a particular hunter or shooter is very much an individual decision. But to deny the benefits of Modern Cartridge Design flies in the face of reality.

The post Modern Cartridge Design: Why New Rifle Cartridges Are Superior to the Classics appeared first on Outdoor Life.

Articles may contain affiliate links which enable us to share in the revenue of any purchases made.

By: John B. Snow

Title: Modern Cartridge Design: Why New Rifle Cartridges Are Superior to the Classics

Sourced From: www.outdoorlife.com/guns/modern-cartridge-design/

Published Date: Fri, 06 Jan 2023 20:27:38 +0000

----------------------------------------------

Did you miss our previous article...

https://manstuffnews.com/weekend-warriors/looking-back-on-the-time-when-122-mule-deer-fell-to-their-deaths-in-the-sierra-nevada

Backyard GrillingWeekend WarriorsAdvice from DadBeard GroomingTV Shows for Guys4x4 Off-Road CarsMens FashionSports NewsAncient Archeology World NewsPrivacy PolicyTerms And Conditions

Backyard GrillingWeekend WarriorsAdvice from DadBeard GroomingTV Shows for Guys4x4 Off-Road CarsMens FashionSports NewsAncient Archeology World NewsPrivacy PolicyTerms And Conditions