Beyond the Dipstick: A Proactive Approach to Truck Longevity

Keeping your truck running strong isn’t about luck; it’s about a systematic, proactive approach to care. Whether you’re hauling heavy loads, navigating treacherous off-road trails, or relying on your vehicle for daily work, a comprehensive maintenance plan is your best defense against costly breakdowns and unexpected downtime. This guide moves beyond the obvious, offering a detailed, interval-based truck maintenance checklist that covers the critical systems you need to monitor. We’ll break down eight essential maintenance areas, from the engine’s core components to the intricate electrical systems and rugged suspension parts that keep you moving forward safely.

Think of this as your strategic blueprint for ensuring reliability, safety, and peak performance. Each section provides actionable steps, specific inspection points, and practical advice tailored for modern trucks. By following a structured routine, you can identify minor issues before they escalate into major, expensive repairs. For those managing multiple vehicles or seeking a more formalized process, you can explore a comprehensive essential vehicle inspection checklist that details crucial checks for modern fleet management. Let’s dive into the checks that separate a well-maintained workhorse from a roadside liability.

1. Engine Oil and Filter Change

Regular engine oil and filter changes are the absolute foundation of any effective truck maintenance checklist. Engine oil serves as the lifeblood of your vehicle, providing critical lubrication to all moving internal components. This process minimizes friction, dissipates heat, and carries away harmful contaminants, preventing premature wear and catastrophic engine failure. Over time, heat and contamination degrade the oil’s protective qualities, making routine replacement essential for long-term engine health and performance.

Why It’s a Top Priority

Failing to change your oil on schedule allows sludge and carbon deposits to build up, which can clog oil passages and starve vital parts of lubrication. This leads to increased friction, higher operating temperatures, and ultimately, severe engine damage. For any truck owner, especially those who tow heavy loads or venture off-road, maintaining a strict oil change regimen is the single most important preventative maintenance task you can perform. It directly impacts your truck’s reliability, fuel efficiency, and resale value.

Implementation and Best Practices

For a comprehensive approach, follow these actionable tips:

- Adhere to Viscosity and Specifications: Always use the specific oil viscosity (e.g., 5W-30, 15W-40) and type (conventional, synthetic blend, or full synthetic) recommended in your truck’s owner’s manual. Using the wrong oil can void your warranty and compromise engine protection.

- Check Levels Weekly: Between changes, make it a habit to check your oil level using the dipstick, preferably when the engine is cool and on a level surface. This helps you spot potential leaks or oil consumption issues early.

- Keep Detailed Records: Maintain a logbook or digital file of every oil change, noting the date, mileage, and type of oil and filter used. This documentation is invaluable for warranty claims and proves a consistent maintenance history to potential buyers.

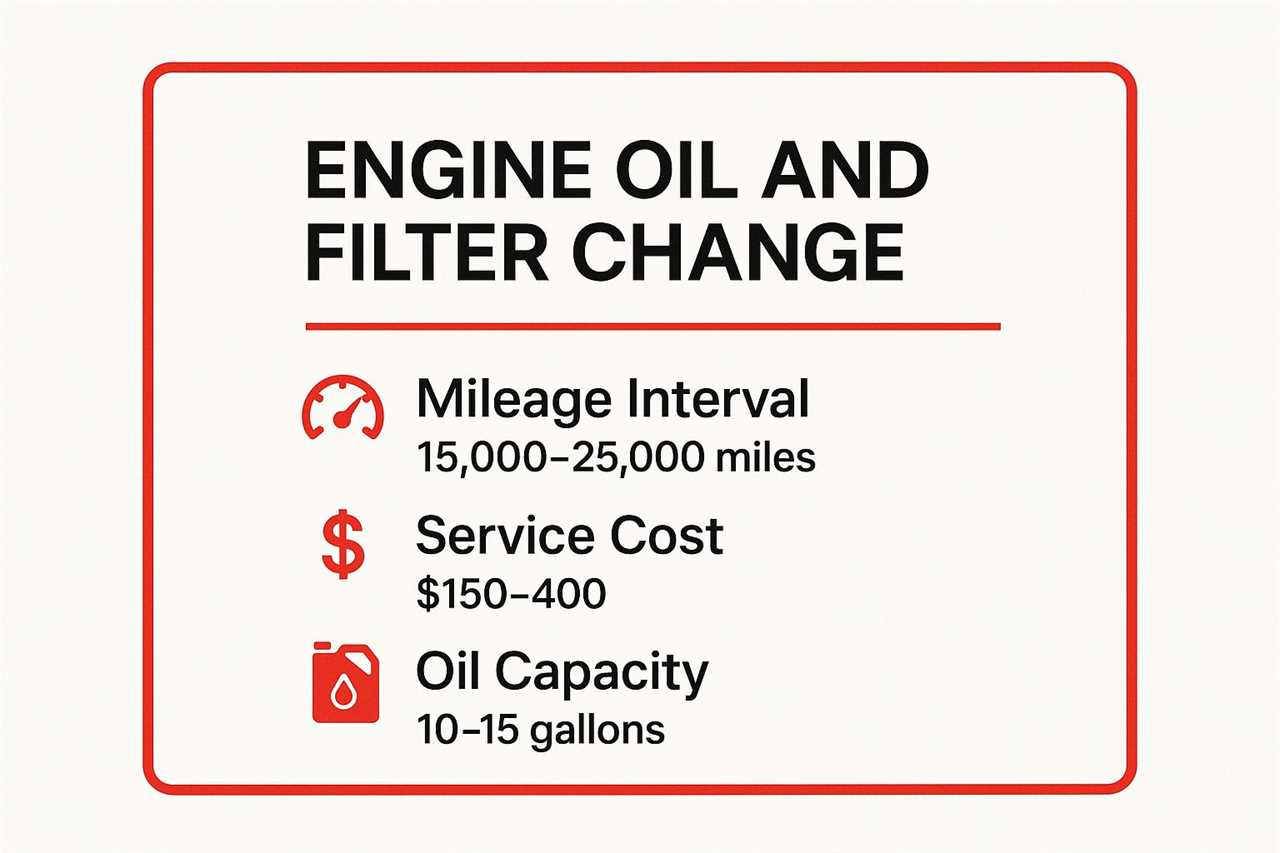

This infographic summarizes the key metrics for a heavy-duty truck oil change, highlighting typical service intervals, costs, and fluid capacities.

As the data shows, servicing a larger truck involves significant fluid volumes and can have extended intervals, especially when using high-quality synthetic oils, making it a critical budget and planning item. A clean engine bay makes spotting leaks easier; you can discover how to clean an engine bay thoroughly to complement your oil service. For a visual guide on performing the change yourself, the video below offers a step-by-step tutorial.

2. Brake System Inspection and Maintenance

A fully functional brake system is arguably the most critical safety component on any truck, making its inspection a non-negotiable part of your truck maintenance checklist. Responsible for stopping thousands of pounds of metal, often under demanding conditions like steep descents or heavy hauling, the brakes must be in perfect working order. This involves a comprehensive check of all parts, including pads, rotors, calipers, drums, and brake fluid, ensuring your truck has the stopping power it needs to keep you and others safe.

Why It’s a Top Priority

Brake failure is not a gradual decline; it is often sudden and catastrophic. Neglecting brake maintenance exposes you to immense risk, as worn pads or low fluid can drastically increase your stopping distance or lead to complete brake loss. For truck owners who tow trailers or navigate challenging terrain, the stakes are even higher. Proactive maintenance not only ensures safety but also prevents more costly repairs down the road, as a failing component can cause a domino effect of damage to other parts of the brake system.

Implementation and Best Practices

To maintain a reliable and responsive brake system, incorporate these habits into your routine:

- Perform Regular Visual Inspections: Once a month, look at your brake pads through the wheel spokes to check their thickness. Also, inspect your rotors for any deep grooves, scoring, or signs of warping. Check your brake fluid reservoir to ensure the level is between the ‘MIN’ and ‘MAX’ lines.

- Listen for Warning Signs: Your brakes will often tell you when something is wrong. Pay close attention to high-pitched squealing, grinding sounds, or a soft, spongy feel in the brake pedal. These are clear indicators that immediate service is required.

- Adhere to Service Intervals: Your owner’s manual provides recommended service intervals for brake fluid flushes and component replacements. Stick to this schedule, as brake fluid absorbs moisture over time, reducing its effectiveness and corroding internal components.

A well-maintained system should operate quietly; you can discover how to eliminate brake noise to diagnose and fix common sound-related issues. Consistent checks and timely service are the best ways to guarantee your truck’s stopping power remains dependable.

3. Tire Inspection and Rotation

Systematic tire maintenance is a non-negotiable part of any comprehensive truck maintenance checklist. Your tires are the only point of contact between your multi-ton vehicle and the road, making their condition directly responsible for handling, braking, and overall safety. A disciplined routine of pressure checks, tread depth measurement, visual inspections, and timely rotations is essential to maximize tire longevity, optimize fuel efficiency, and ensure safe, predictable performance under all conditions.

Why It’s a Top Priority

Neglecting your tires can lead to catastrophic failures like blowouts, which are especially dangerous in a high-profile vehicle like a truck. Beyond safety, improper inflation is a leading cause of premature and uneven wear, drastically shortening the life of your expensive tires. Underinflated tires also increase rolling resistance, forcing your engine to work harder and consuming more fuel. For instance, fleets like J.B. Hunt utilize advanced tire pressure monitoring systems to mitigate these risks, while independent truckers often report over $3,000 in annual savings just from diligent tire care.

Implementation and Best Practices

To integrate professional-grade tire care into your routine, follow these actionable tips:

- Check Pressure Weekly: Always check tire pressure when the tires are cold (before driving) using a quality pressure gauge. Adjust the pressure according to the load you are carrying, referencing the sticker on the driver’s side doorjamb, not the maximum pressure listed on the tire sidewall.

- Rotate Every 6,000-8,000 Miles: Regular rotations, following the pattern recommended in your owner’s manual, are crucial for promoting even tread wear. This simple habit can extend tire life significantly, with some programs like Penske’s achieving up to a 15% increase in tire lifespan.

- Conduct Visual Inspections: Regularly inspect your tires for cuts, punctures, bulges, or any foreign objects embedded in the tread. Also, check your tread depth using the “penny test” or a dedicated gauge to ensure it’s above the legal minimum of 2/32 of an inch.

- Maintain Detailed Records: Keep a log of when you rotate your tires and any pressure adjustments or inspections. This data helps you track performance and spot wear patterns that might indicate an underlying alignment or suspension issue.

Proper tire selection is just as important as maintenance. If you’re looking to upgrade, you can explore this guide on how to choose all-terrain tires for your truck to find the perfect fit for your needs.

4. Cooling System Maintenance

A truck’s cooling system is the primary defense against engine overheating, a critical issue that can lead to catastrophic damage, especially when towing heavy loads or navigating challenging terrain. This system circulates coolant, or antifreeze, through the engine to absorb excess heat and then dissipates it through the radiator. Proper maintenance ensures the engine operates within its optimal temperature range, safeguarding performance, preventing gasket failures, and extending engine life. Neglecting this part of your truck maintenance checklist can result in costly repairs and leave you stranded.

Why It’s a Top Priority

An inefficient cooling system allows engine temperatures to skyrocket, which can cause cylinder heads to warp, gaskets to blow, and internal components to fail. For trucks used in demanding applications, like long-haul operations in desert climates or construction fleets operating in dusty environments, the strain on the cooling system is immense. For instance, Ryder System famously reduced its fleet’s cooling system failures by 40% simply by implementing a more rigorous preventive maintenance program. This highlights how proactive care directly translates to improved reliability and lower operational costs.

Implementation and Best Practices

To keep your engine cool under pressure, integrate these habits into your routine:

- Inspect Hoses and Connections: During your regular checks, visually inspect all coolant hoses for cracks, bulges, or mushiness. Check the connections and clamps for tightness and signs of leaks, which often appear as colored residue (typically green, orange, or pink) around the fittings.

- Test Coolant Concentration: Use a simple and inexpensive antifreeze tester to check the coolant’s concentration seasonally. The ideal mixture is typically 50/50 antifreeze and distilled water, providing both freeze and boil-over protection. This is especially important before winter and summer.

- Keep the Radiator Clean: Dirt, bugs, and road debris can clog the radiator’s external fins, severely restricting airflow and reducing its ability to dissipate heat. In dusty or off-road conditions, make it a point to regularly clean the radiator fins with a soft brush and low-pressure water.

- Adhere to Coolant Flush Intervals: Coolant degrades over time, losing its anti-corrosive properties. Consult your owner’s manual for the recommended flush and replacement interval (often every 30,000 to 100,000 miles, depending on the coolant type) and stick to it.

5. Air Filter Replacement

A clean air filter is fundamental to your truck’s engine health and efficiency, acting as the lungs of the intake system. Its job is to block dust, debris, and other airborne contaminants from entering the engine, where they can cause abrasive wear on cylinders, pistons, and rings. A clogged filter restricts airflow, forcing the engine to work harder, which hurts fuel economy and robs the vehicle of power. This makes regular inspection and replacement a non-negotiable part of any comprehensive truck maintenance checklist.

Why It’s a Top Priority

Neglecting the air filter can lead to a cascade of negative effects beyond just poor performance. A severely restricted filter can create a rich air-fuel mixture, leading to fouled spark plugs, increased carbon deposits, and higher emissions. For trucks operating in demanding environments, like dusty construction sites or agricultural fields, a clogged filter is a primary cause of accelerated engine wear. For instance, waste management fleets often replace air filters monthly due to constant exposure to dust, while mining trucks may require weekly inspections to prevent catastrophic engine damage.

Implementation and Best Practices

To ensure your engine breathes clean air, incorporate these practices into your routine:

- Inspect Frequently in Harsh Conditions: If you frequently drive on dirt roads, through construction zones, or in other dusty environments, don’t wait for the recommended service interval. Visually inspect your air filter every few thousand miles by holding it up to a light source; if you can’t see light through it, it’s time for a replacement.

- Use High-Quality Filters: Always opt for OEM or high-quality aftermarket filters that meet or exceed original specifications. Cheaper, poorly constructed filters may not seal properly or could have inferior filtration media, allowing harmful particles to bypass the filter and enter your engine.

- Check the Entire Intake System: When replacing the filter, take a moment to inspect the airbox and intake tube for cracks, loose clamps, or other signs of leaks. An unsealed intake system can allow unfiltered air to enter the engine, completely negating the purpose of a clean filter.

- Keep a Spare on Hand: For those who venture far off-road or travel in remote areas, carrying a spare air filter is a smart move. It allows for a quick roadside replacement if the primary filter becomes unexpectedly saturated with dust or water.

6. Transmission and Drivetrain Service

Beyond the engine, the transmission and drivetrain are responsible for converting power into motion, making their maintenance a critical part of any comprehensive truck maintenance checklist. This service involves managing the health of your transmission fluid, transfer case fluid, and differential oils. These specialized fluids cool, clean, and lubricate gears and clutches, ensuring smooth power transfer from the engine to the wheels and preventing the premature failure of incredibly expensive components.

Why It’s a Top Priority

Neglecting your drivetrain fluids is a costly gamble. As transmission fluid degrades, it loses its ability to manage heat, leading to varnish buildup, slipping clutches, and harsh shifts. Similarly, contaminated differential oil can quickly destroy the precise gearing inside your axles, a repair that can cost thousands. For truck owners who tow heavy loads or frequently engage their 4×4 systems, these fluids are subjected to extreme stress and heat, accelerating their breakdown. Proper service ensures reliability under pressure and prevents catastrophic failures on the road or trail.

Implementation and Best Practices

To properly maintain your truck’s entire drivetrain, integrate these practices into your routine:

- Strictly Adhere to Fluid Specifications: Your truck’s transmission, transfer case, and differentials require very specific fluid types (e.g., ATF+4, Mercon LV, 75W-90 gear oil). Using a generic or incorrect fluid can cause severe damage and void warranties. Always consult your owner’s manual.

- Check for Leaks and Proper Levels: Regularly inspect the ground under your truck for red (transmission) or dark, thick (differential) fluid spots. Periodically check fluid levels according to your manual’s procedure; some transmissions have dipsticks, while others have fill plugs that require the vehicle to be level.

- Adjust Service Intervals for Severe Use: If your truck usage includes frequent towing, hauling heavy cargo, or extensive off-roading, you must shorten the manufacturer’s recommended service intervals. For example, many construction companies perform differential service every 50,000 miles to cope with harsh conditions.

- Don’t Just Drain-and-Fill: For automatic transmissions, a simple drain-and-fill only replaces about half the fluid. A complete fluid exchange or flush performed by a professional is often a better option to remove all old, degraded fluid from the torque converter and cooler lines.

7. Electrical System and Battery Maintenance

A modern truck’s electrical system is its central nervous system, managing everything from engine performance and safety features to infotainment and lighting. This complex network includes the battery, alternator, starter, and miles of wiring. Proper maintenance is no longer just about preventing a dead battery; it’s about ensuring the reliable operation of critical systems that impact your truck’s safety, efficiency, and overall functionality. A single corroded connection or a failing alternator can sideline your vehicle unexpectedly.

Why It’s a Top Priority

Neglecting the electrical system can lead to a cascade of frustrating and expensive problems. A weak battery can strain the alternator, causing premature failure, while frayed wiring can create short circuits that damage sensitive electronic control units (ECUs). For truck owners who rely on their vehicles for work or remote adventures, a sudden electrical failure is more than an inconvenience; it can be a critical safety issue. Consistent electrical checks are a cornerstone of any comprehensive truck maintenance checklist, safeguarding against everything from no-start conditions to the failure of advanced driver-assist systems.

Implementation and Best Practices

To maintain a healthy electrical system, integrate these practices into your routine:

- Clean and Inspect Battery Terminals: At least once a month, inspect battery terminals for corrosion, a white or greenish powdery buildup. Disconnect the terminals (negative first, then positive) and clean them with a wire brush and a baking soda/water solution to ensure a solid connection.

- Test Battery Before Seasonal Changes: Before winter arrives, have your battery professionally load-tested. Cold weather significantly reduces a battery’s cranking power, and a test can identify a weak unit before it leaves you stranded on a freezing morning.

- Inspect Wiring During Other Services: Whenever you’re under the hood for an oil change or other service, take a moment to visually inspect visible wiring harnesses. Look for signs of cracking, fraying, or heat damage, especially near the engine or exhaust components.

- Use a Battery Maintainer for Storage: If your truck will be parked for several weeks or more, connect a smart battery maintainer or trickle charger. This prevents the battery from discharging and extends its lifespan.

Proper inspections are crucial for safety in all contexts. Just as trucks require thorough electrical checks, property safety relies on a detailed electrical inspection checklist to identify hazards and ensure compliance.

8. Suspension and Steering System Inspection

A truck’s suspension and steering systems are fundamental to its safety, stability, and handling characteristics. These systems work together to absorb road imperfections, keep tires in firm contact with the ground, and allow the driver to maintain precise control. A comprehensive inspection of these components is a non-negotiable part of any truck maintenance checklist, as it directly impacts driver comfort, prevents premature tire wear, and ensures the vehicle responds predictably in all conditions.

Why It’s a Top Priority

Neglecting the suspension and steering can lead to a host of dangerous issues, including poor handling, excessive body roll in turns, and a loss of control during emergency maneuvers. Worn components like shock absorbers, bushings, or ball joints can cause uneven tire wear, leading to costly replacements and reduced traction. For truck owners who tow or go off-road, a robust and well-maintained suspension is even more critical to manage heavy loads and navigate challenging terrain safely. For example, vocational trucks in construction often require monthly suspension inspections due to the extreme stress they endure.

Implementation and Best Practices

To properly maintain your truck’s handling and stability, integrate these practices into your routine:

- Look for Irregular Tire Wear: One of the clearest signs of a suspension or alignment problem is uneven wear on your tires. Look for “cupping” (scalloped dips), excessive wear on the inner or outer edges, or feathering across the tread.

- Inspect Shocks and Struts: Visually check your shock absorbers and struts for any signs of fluid leaks. A leaking shock has lost its damping ability and must be replaced. You can also perform a “bounce test” by pushing down firmly on each corner of the truck; if it bounces more than once or twice, the shocks are likely worn.

- Check for Steering Play: With the truck parked, turn the steering wheel lightly from side to side. There should be very little “play” or looseness before the wheels begin to turn. Excessive play could indicate worn tie rod ends, a failing steering rack, or other linkage issues.

- Get a Professional Alignment: Have your wheel alignment checked and adjusted annually, or any time you install new tires or replace suspension components. Proper alignment is crucial for handling and is a proven cost-saver; some line-haul trucking companies have reduced their tire costs by up to 25% through diligent alignment programs.

Truck Maintenance Checklist Comparison

| Maintenance Type |

Implementation Complexity

|

Resource Requirements

|

Expected Outcomes

|

Ideal Use Cases

|

Key Advantages

|

| Engine Oil and Filter Change |

Moderate – routine service, requires scheduled downtime |

Medium – oil, filter, disposal management |

Extends engine life, improves fuel efficiency |

All heavy-duty trucks, long-haul fleets |

Prevents engine wear, reduces maintenance costs |

| Brake System Inspection and Maintenance |

High – requires specialized knowledge, diagnostics |

High – parts, tools, expert labor |

Ensures safety, prevents violations and accidents |

Trucks with air brakes, high-load/frequent stops |

Critical for safety, legal compliance |

| Tire Inspection and Rotation |

Moderate – time-intensive for multi-axle vehicles |

Medium – pressure gauges, rotation tools |

Longer tire life, better fuel economy, safety |

Fleets emphasizing fuel savings and safety |

Extends tire life, prevents breakdowns |

| Cooling System Maintenance |

Moderate – involves multiple components and fluid handling |

Medium – coolant, cleaning supplies |

Prevents overheating, extends engine parts life |

Trucks in harsh or extreme climates |

Reduces costly engine damage risks |

| Air Filter Replacement |

Low – simple replacement, frequent intervals |

Low – filters, inspection tools |

Improves fuel efficiency, protects engine |

Dusty or urban environments needing clean air |

Enhances engine and cabin air quality |

| Transmission and Drivetrain Service |

High – complex fluids and components, specialized tools |

High – fluids, parts, diagnostic equipment |

Prevents transmission failure, smooth operation |

Heavy-duty trucks with severe duty cycles |

Extends drivetrain life, improves fuel efficiency |

| Electrical System and Battery Maintenance |

Moderate to high – complex diagnostics, wiring checks |

Medium – test equipment, battery maintenance items |

Reliable starts, reduced breakdowns |

All modern trucks, cold-climate operations |

Maintains system reliability, reduces downtime |

| Suspension and Steering System Inspection |

High – specialized equipment, detailed inspection |

Medium to high – alignment tools, replacement parts |

Improved handling, extended tire life |

Trucks needing stability, load security |

Enhances safety and driver comfort |

Integrating Your Checklist for Peak Truck Performance

A detailed truck maintenance checklist is more than just a list of tasks; it’s a dynamic roadmap to reliability, performance, and long-term value. We’ve navigated through the eight essential pillars of truck care, from the lifeblood of your engine oil and the critical stopping power of your brakes to the complex harmony of your electrical and suspension systems. Each component, whether it’s a fresh air filter or a properly torqued lug nut, plays an indispensable role in the overall health of your vehicle.

The true power of this knowledge, however, is unlocked through consistent application. Simply knowing what to check is only the first step. The goal is to transform this checklist from a passive document into an active, integrated part of your ownership experience.

From Checklist to System: Creating a Maintenance Rhythm

The most significant takeaway is to establish a documented maintenance rhythm. This moves you from reactive repairs to proactive care, saving you from costly breakdowns and unexpected downtime on the trail or the job site.

- Choose Your Method: Whether you prefer a rugged, oil-stained logbook kept in the glove compartment, a simple spreadsheet on your computer, or a dedicated vehicle maintenance app on your phone, the key is consistency. Record the date, mileage, and specific service performed for every item on your checklist.

- Build a Vehicle History: This log becomes your truck’s medical record. It provides invaluable insight into its health, allowing you to spot patterns. Is a specific fluid level consistently low? Are brake pads wearing out faster than expected? This data empowers you to diagnose underlying issues before they become catastrophic failures.

- Anticipate Future Needs: A detailed service history helps you budget for and schedule future maintenance. Knowing your transmission fluid is due for a change in 5,000 miles or your tires will need replacing before the winter season gives you control over your finances and schedule.

For those managing multiple vehicles, whether for a small business or a family of enthusiasts, scaling this process is crucial. To truly maximize efficiency and ensure the ongoing performance and longevity of your fleet, integrating your maintenance checklist with broader solutions like essential fleet management systems can provide significant benefits. These platforms can automate reminders, track expenses, and provide a high-level view of your entire fleet’s health.

Ultimately, mastering this disciplined approach is the single greatest investment you can make in your truck. It’s the foundation upon which every off-road adventure, cross-country haul, and daily commute is built. A well-maintained truck isn’t just more dependable; it’s safer for you and your passengers and retains significantly more value over its lifetime. Think of every oil change, tire rotation, and fluid check as a deposit into your truck’s bank of reliability.

Your journey to becoming a more capable and confident truck owner starts in the garage. This comprehensive truck maintenance checklist is your guide, but the real expertise comes from hands-on experience and a community of fellow enthusiasts.

Ready to take your knowledge to the next level with expert guides on gear, recovery techniques, and trail-tested advice? Explore the extensive resources at Offroading.com to connect with a community dedicated to getting the most out of every adventure.

Article created using Outrank

https://offroading.com/truck-maintenance-checklist/?utm_source=rss&utm_medium=rss&utm_campaign=truck-maintenance-checklist

Did you miss our previous article...

https://manstuffnews.com/4x4-off-road-cars/7-essential-off-road-recovery-gear-items-for-2025

Backyard GrillingWeekend WarriorsAdvice from DadBeard GroomingTV Shows for Guys4x4 Off-Road CarsMens FashionSports NewsAncient Archeology World NewsPrivacy PolicyTerms And Conditions

Backyard GrillingWeekend WarriorsAdvice from DadBeard GroomingTV Shows for Guys4x4 Off-Road CarsMens FashionSports NewsAncient Archeology World NewsPrivacy PolicyTerms And Conditions