Getting the right measurements is crucial when swapping out your shocks. You need two key numbers: the fully extended length and the fully compressed length. These figures define the shock’s working range and ensure your new parts match your suspension.

Messing this up means you’re throwing money away on parts that won’t fit or perform correctly.

The Two Measurements That Matter Most

Before you start measuring, understand what you’re measuring. We need the travel of your vehicle’s suspension, not just the old shock. The old shock could be worn out or the wrong size, leading to bad readings.

The basic idea is simple. You will measure the distance between the shock mounting points at full droop (extended) and full bump (compressed). This gives you the absolute travel limits of your suspension.

Defining Your Shock’s Operating Range

These two numbers—extended and compressed—define the shock’s “travel.” Travel is the difference between the two measurements. Getting this wrong can cause serious problems on the trail.

A shock that’s too long will bottom out before your bump stops, which can destroy the shock and its mounts. A shock that’s too short will top out, limiting suspension travel and creating a harsh ride.

Taking time to get these values right is the foundation for a successful shock upgrade. For more on picking components, read our guide on how to choose shocks for your truck.

Getting The Right Tools For The Job

Before crawling under your rig, let’s talk about tools. You cannot get an accurate shock measurement without the right gear. You don’t need a professional shop, but essential items will prevent headaches.

Think of it as a pre-flight check. A little prep work makes the process smoother and gets you back on the trail faster.

Your Essential Tool Checklist

Let’s get your gear in order before you lift the vehicle. Safety is everything, so do not cut corners on jack stands or wheel chocks.

- Floor Jack: A reliable floor jack is necessary for lifting the frame and allowing the suspension to move.

- Jack Stands: Never work under a vehicle held up only by a jack. You need at least two quality jack stands rated for your vehicle’s weight.

- Wheel Chocks: These are non-negotiable and stop your rig from rolling while you work.

- Quality Tape Measure: A sturdy, easy-to-read tape measure is critical for getting accurate numbers.

- Safety Glasses: Wear these to protect your eyes from dirt and rust that can fall from the undercarriage.

It’s not just about tools; it’s about your workspace. An organized area makes a big difference. For those serious about DIY work, setting up an efficient automotive workshop can improve safety and efficiency.

How To Measure Extended Shock Length

First, you need to find the shock’s extended length. This is a critical measurement you get when your suspension is at “full droop.”

To do this, you must lift the frame so the axle and wheels hang freely. This lets gravity show you the maximum travel your setup allows.

Safety is non-negotiable. Use a floor jack on a solid part of the frame and secure the vehicle with rated jack stands. If you’re on uneven ground, stabilizing your vehicle is key, and some principles from our how to use a winch guide can help.

Once the axle hangs at full droop, grab your tape measure. Measure from the center of the upper shock mount to the center of the lower shock mount.

- For eyelet mounts: Measure from the center of the top bolt hole to the center of the bottom bolt hole.

- For stud mounts: Measure from the stud’s base (where it meets the bracket) to the eyelet’s center. Do not measure from the tip of the stud.

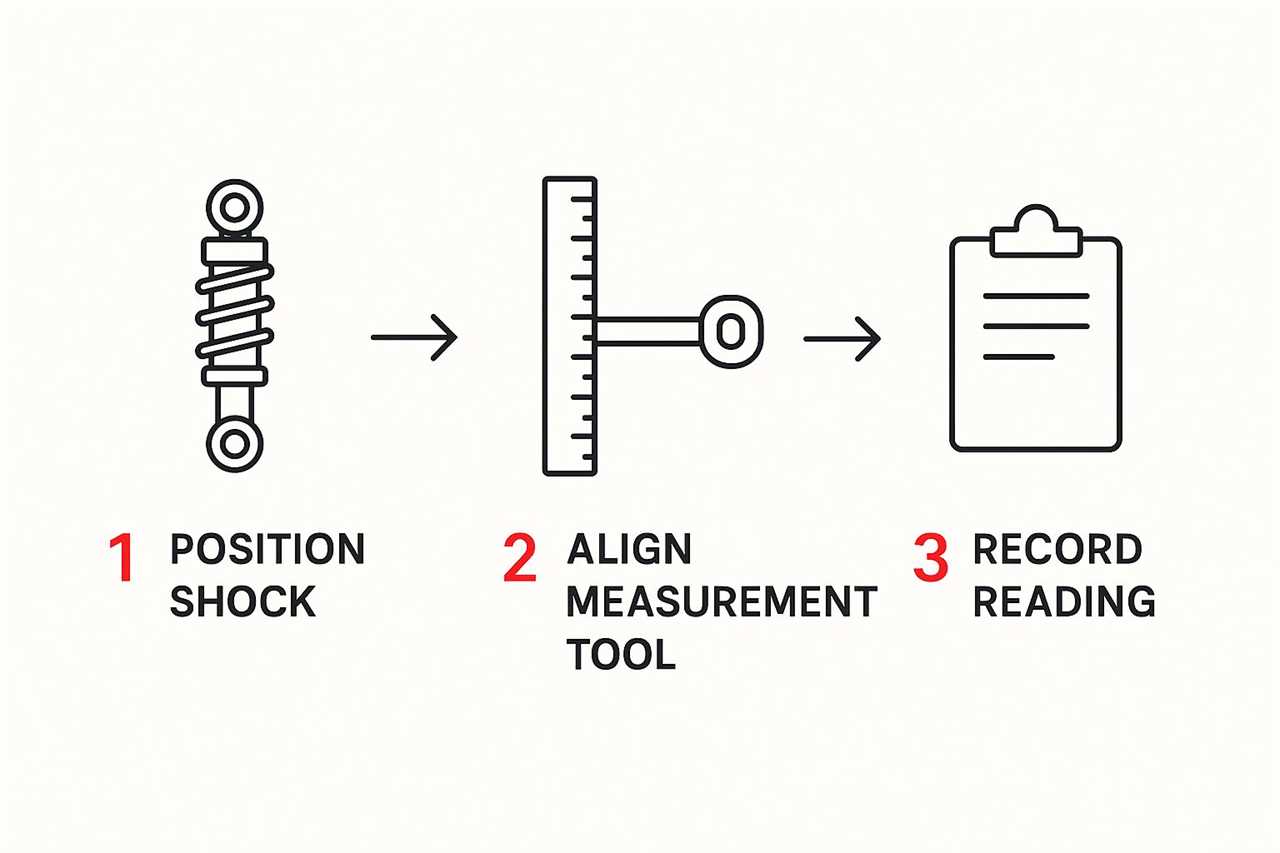

This image shows exactly where to measure.

The process is simple, but you must be methodical to get it right. Position the rig, get your droop, and measure carefully from the correct points.

Avoiding Common Measurement Errors

A frequent mistake is measuring to the end of a stud mount instead of its base. This can add an inch or more to your measurement, which is a huge deal.

This error leads you to order shocks that are too long. An oversized shock will bottom out before your suspension does, destroying the shock and possibly its mounts.

Double-check your measurement points. Always measure from the center of an eyelet or the base of a stud. Getting the extended length right is the foundation for the next steps.

Finding Your Compressed Shock Length Safely

Getting the compressed length is tricky but critical. This measurement requires you to cycle your suspension to its maximum “up travel.” Doing this safely and accurately is the whole game.

You are mimicking what your truck does when it hits a big obstacle. The goal is to find the shortest distance between your shock mounts without breaking anything.

Real-World Compression Methods

The most practical way to get this measurement is to use the vehicle’s weight. Slowly drive one tire onto a curb or a solid automotive ramp. Another method is using a floor jack under the axle to push the wheel into the fender well.

Here’s a pro tip: remove the jounce bumper (bump stop) before you take this measurement. If you can’t remove it, account for how much it will compress. This prevents picking a shock that bottoms out before the bump stop can work.

To get your compressed length, fully stuff the suspension using your ramp or jack. Then, measure the distance between the two shock mounting points.

As a rule, subtract about half an inch from this number. This wiggle room accounts for the bump stop compressing and protects your suspension. For more details, see the guide on safe shock measurement at ShockWarehouse.com.

This adjustment gives your suspension the buffer it needs. It ensures the bump stop takes the final impact, not your new shocks.

Why Precision Is Crucial For Performance

When ordering new shocks, “close enough” is not good enough. In suspension, even a quarter-inch mistake can throw your rig out of whack. Inaccurate measurements lead to ordering the wrong part, which harms ride quality and can make your vehicle unsafe.

Precision is everything.

This is about the health of your whole suspension system. Shocks, springs, and tires work in harmony. The wrong shock length creates a weak link, much like how wrong-sized tires affect your speedometer. If overhauling your setup, see our guide on how to pick and measure ATV tires correctly.

The Science Of Accuracy

Professional suspension engineers use sophisticated sensors for hyper-accurate measurements. They know that tiny discrepancies can have a massive impact on performance.

In a lab, factors like a time constant to pulse duration ratio (τ/T) of 10 can create a 10% measurement error.

This highlights why being meticulous with a tape measure is so important. A careful measurement is your best defense against buying shocks that will fail or damage your rig.

While you can get it right yourself, don’t hesitate to seek a second opinion. For complex jobs, professional shocks and struts services are a smart move to protect your investment.

Common Questions About Measuring Shocks

When you’re learning how to measure shocks, a few questions always come up. Getting the right answers from the start can save you headaches and money. It’s about ordering the right parts the first time.

People often ask if they should measure the old shock. The answer is no, you should not. The only reliable method is measuring the mounting points on your vehicle while cycling the suspension.

Critical Fitment Questions

So, what if your measurements are slightly off? In suspension, “close enough” can lead to big consequences.

- What if a shock is too long? A shock that is too long will bottom out before your bump stops. This can destroy the shock’s internal valving and damage your vehicle’s mounting points.

- What if a shock is too short? A shock that is too short will limit your suspension’s downward travel, or “droop.” This causes a harsh topping-out clunk and hurts off-road articulation.

The bottom line is to always double-check your numbers. Taking an extra five minutes for accuracy prevents wasting money on parts that won’t fit or will break other components.

Lift Kits And Shock Terminology

Off-roaders often wonder how a lift kit changes things. A lift kit completely alters your suspension geometry, making factory shock lengths useless. You must measure your vehicle’s new travel range to find the correct lengths.

Finally, let’s clarify the difference between shock length and shock travel.

- Shock Length: These are the two static numbers you measure—the fully extended and fully compressed lengths between the mounts.

- Shock Travel: This is the shock’s actual working range, found by subtracting the compressed length from the extended length.

Knowing your required travel is crucial. It ensures the shock you buy will work properly within your suspension’s full range of motion.

For more expert guides and tutorials to get your rig ready for any trail, explore the resources at Offroading.com. Find everything you need at https://www.offroading.com.

https://offroading.com/how-to-measure-shock-length/?utm_source=rss&utm_medium=rss&utm_campaign=how-to-measure-shock-length

Did you miss our previous article...

https://manstuffnews.com/4x4-off-road-cars/12-best-portable-solar-panels-for-camping-in-2025

Backyard GrillingWeekend WarriorsAdvice from DadBeard GroomingTV Shows for Guys4x4 Off-Road CarsMens FashionSports NewsAncient Archeology World NewsPrivacy PolicyTerms And Conditions

Backyard GrillingWeekend WarriorsAdvice from DadBeard GroomingTV Shows for Guys4x4 Off-Road CarsMens FashionSports NewsAncient Archeology World NewsPrivacy PolicyTerms And Conditions