Understanding Your Load Requirements Through Real-World Examples

The old “multiply your vehicle’s weight by 1.5” rule is a decent starting point for picking a winch. But if you stop there, you’re setting yourself up for a long walk home. Real-world recoveries are messy, and the number on your door jamb sticker—the Gross Vehicle Weight Rating (GVWR)—doesn’t tell the whole story. The environment itself is a powerful force that can easily overwhelm an under-specced winch.

Imagine your 5,500-pound SUV isn’t just parked on pavement; it’s bogged down to the axles in thick, sticky mud. That mud creates a powerful suction, adding a huge amount of resistance. Suddenly, you’re not just pulling 5,500 pounds. You might be fighting an extra 50% to 100% of that weight just to break free. This is a classic scenario where a simple calculation fails because you’re battling the terrain, not just the vehicle.

The Impact of Angles and Inclines

Let’s look at another common situation. Your truck slides off a slippery trail and ends up tilted at a 30-degree angle against a hill. To pull it back onto the path, your winch now has to fight gravity in addition to the vehicle’s dead weight. A steep incline can easily double the effective load on your winch. Even a slight off-angle pull, where your anchor point isn’t straight ahead, adds friction and strain that demand more power.

This isn’t just an off-roading problem. The same principles apply in heavy industries. The global winch market is expected to reach USD 3.7 billion by 2037, largely because sectors like construction, marine, and energy understand these forces all too well. When you’re moving multi-ton equipment, getting the math right is non-negotiable for safety and getting the job done. You can find out more about these industrial winch trends and market projections to see how critical this is on a larger scale.

Real-World Applications and Required Force

To truly grasp how load changes, it’s helpful to compare different scenarios. What works for a lightweight ATV won’t cut it for a fully loaded work truck. The table below breaks down some common applications and the kind of winch capacity they demand.

Load Capacity Requirements by Application

Comparison of typical load requirements across different industries and use cases

| Application |

Typical Load Range |

Recommended Winch Capacity |

Safety Factor |

| ATV/UTV |

Stuck in shallow mud or on a moderate trail incline. |

3,500 – 5,500 lbs |

1.5x |

| Light SUV/Jeep |

Deep mud, sand recovery, or moderate rock crawling. |

9,500 – 12,000 lbs |

1.5x – 2.0x |

| Full-Size Truck |

Heavily loaded, stuck on a steep, wet incline. |

12,000 – 16,500 lbs |

2.0x |

| Marine/Industrial |

Pulling heavy equipment onto a trailer or dock. |

15,000+ lbs |

2.0x – 3.0x |

As you can see, as the vehicle weight, potential for resistance, and stakes get higher, both the winch capacity and the safety factor need to increase. If there’s one thing to remember, it’s this: always plan for the worst-case scenario you’re likely to face, not the easiest one.

The Safety Margin That Could Save Your Equipment (And Your Life)

Getting by with the absolute minimum 1.5x safety factor might get you a passing grade on paper, but out on the trail, you want an A+. Relying on that bare minimum is a huge gamble that seasoned off-roaders and equipment failure investigators have seen go wrong countless times. This isn’t just being overly cautious; it’s about respecting the massive, unpredictable forces you’re dealing with when you’re in a jam. Figuring out what size winch you need means looking past the simple math and planning for what could happen, not just what you hope will happen.

Let’s put it this way: a 9,500-pound winch might seem like a solid choice for your 6,000-pound rig. But remember, that 9,500-pound rating is only for the very first wrap of rope on the drum, tested in perfect lab conditions. As you spool out more line to reach your anchor point, the winch’s actual pulling power drops off a cliff. Now, factor in a sun-bleached synthetic rope or a slightly kinked steel cable, and your trusty 9,500-pound winch might only be giving you 7,000 pounds of force when you need it most.

When 1.5x Isn’t Enough: Real-World Risks

That standard safety margin often doesn’t account for the violent, jarring reality of a tough recovery. The biggest threat is shock loading. This happens when the winch line suddenly snaps from slack to taut—imagine your vehicle gaining a bit of traction and then sliding back abruptly. That jolt can spike the load on your winch well beyond its rated capacity, leading to catastrophic failure of the gears, the motor, or the rope itself.

These hidden forces are exactly why professionals always push for bigger safety margins. Here are some situations where you should definitely aim higher than the minimum:

- High-Consequence Recoveries: If a winch failure could mean serious vehicle damage, personal injury, or environmental harm, a 2.0x safety factor should be your starting point.

- Extreme Conditions: Getting stuck in deep mud, murky water, or on a steep, slippery incline adds a ton of extra resistance. These factors can easily demand a 2.0x or even 2.5x margin.

- Commercial or Life-Safety Operations: For any job where a person’s safety is on the line, a 3.0x or higher margin is often the required standard, no exceptions.

The market for specialized safety winches, which is expected to reach USD 2,050.4 million in 2025, reflects just how critical this is. In demanding industrial fields, manufacturers know that an undersized winch is a disaster waiting to happen and insist that a 1.5x margin is the absolute floor for safe use. You can read more about these safety winch market trends to see how seriously the pros take this. Building in a solid safety margin isn’t just a good idea—it’s a core part of a smart and safe recovery. To get the full picture, take a look at our guide on how to use a winch correctly.

Vehicle Weight vs. Winch Capacity: Breaking The Dangerous Myth

Let’s get one thing straight: if you own a 6,000-pound truck, a 6,000-pound winch is next to useless. This is probably the single most dangerous and costly misunderstanding in the off-road community. The Gross Vehicle Weight Rating (GVWR) you see on your door sticker is just the starting point, not the whole story. The real forces you’re fighting in a recovery situation are much, much higher. To truly answer “what size winch do I need,” you have to understand the physics of being stuck.

When your truck is buried to its axles in thick, suction-cupped mud, the resistance can easily add 100% of your vehicle’s weight to the pull. Suddenly, your 6,000-pound rig effectively weighs 12,000 pounds. Or what if you’re stuck on a steep hill? Gravity becomes a massive force multiplier. A vehicle on a 45-degree slope requires a pull nearly equal to its own weight just to fight gravity, and that’s before you even account for the mud, rocks, or ruts holding you back.

How Different Scenarios Multiply Forces

These multiplying forces aren’t just hypotheticals; they’re the harsh reality of every tough recovery. A simple weight-to-capacity match-up doesn’t account for the dynamic variables that can quickly cook an undersized winch, leaving you in a worse spot than when you started. To figure out your real needs, you have to picture the worst-case scenario you might encounter.

- Deep Mud or Sand: That suction effect is no joke. I’ve seen mid-size SUVs weighing around 5,000 pounds require a pull of 10,000 pounds or more just to break free from sticky mud.

- Steep Inclines: Trying to pull a rig up a steep, rocky trail combines the vehicle’s dead weight with rolling resistance and the powerful pull of gravity. A recovery that looks simple can easily double the force your winch needs to generate.

- Combined Factors: Now, imagine the ultimate bad day: your fully-loaded truck is bogged down in mud while parked on an incline. The forces start to stack up. You’re fighting the mud’s suction, the incline’s angle, and the vehicle’s dead weight. This is precisely where a winch rated for 2.0x to 2.5x your GVWR isn’t just a luxury; it’s a critical tool for a safe and successful extraction.

The Professional’s Rule of Thumb

This is exactly why seasoned off-roaders and professional recovery crews scoff at the idea of a 1:1 weight-to-capacity ratio. They know from experience that a winch needs a power reserve. It has to handle the shock loads from a taught line, the unexpected drag from a hidden rock, and the less-than-perfect pulling angles that are common in the real world.

The absolute bare minimum you should ever consider is a winch with a capacity of 1.5x your GVWR. But if you’re serious about being prepared for tough situations, aiming for 2.0x is the smarter, safer bet. That extra power isn’t just for show; it’s your ticket home when things go sideways.

How Your Rope Choice Affects Real-World Capacity

The number printed on the side of your winch is an ideal-world figure, but the rope spooled onto the drum is what dictates performance when things get messy. A 9,000-pound winch might sound like overkill, but if you pair it with a worn-out or wrong-sized rope, you could find yourself struggling to pull 6,000 pounds when you’re buried up to the axles. The choice between old-school steel cable and modern synthetic rope is one of the biggest decisions affecting your real pulling power and, more importantly, your safety on the trail.

Steel Cable vs. Synthetic Rope

For decades, steel cable was the only game in town. It’s undeniably tough, shrugs off abrasion from rocks and grit, and is generally easier on the wallet. But that’s where the advantages start to thin out. Steel is heavy, a pain to handle, and notorious for developing sharp, hand-shredding burrs. Worse, it stores a terrifying amount of kinetic energy when under load. If a steel cable snaps, it becomes a destructive whip that can cause serious injury or vehicle damage. A kinked or rusted steel cable can also lose up to 40% of its strength, silently destroying your safety margin.

This is where synthetic rope comes in. It’s incredibly light—often 80% lighter than its steel counterpart—making it much easier to carry and manage, especially in a stressful recovery situation. It doesn’t store that dangerous energy, so if it fails, it typically just drops to the ground. While it costs more and needs protection from abrasion and UV damage, its strength-to-weight ratio is far superior. Proper care is key, but the safety benefits are a huge reason so many seasoned off-roaders have made the switch. For a deeper dive, check out our guide on choosing between wire cable and synthetic rope for your winch.

To help you visualize the trade-offs, here’s a quick comparison of the two main rope types.

Rope Type Performance Comparison

Detailed comparison of steel cable vs synthetic rope performance characteristics

| Rope Type |

Breaking Strength |

Weight |

Durability |

Best Applications |

| Steel Cable |

Very high |

Heavy |

Excellent abrasion resistance, but prone to rust and kinking which severely reduces strength. |

Rocky terrain, industrial use, budget-conscious builds. |

| Synthetic Rope |

Extremely high for its weight |

Very light (up to 80% lighter than steel) |

Susceptible to abrasion and UV damage, but easy to repair in the field. |

Most recreational off-roading, competitions, situations where safety and ease of handling are paramount. |

The takeaway here is that while steel is tough against abrasion, synthetic rope offers superior safety and handling, making it the preferred choice for most modern off-roaders.

Why Rope Condition Is Everything

No matter what material you choose, the condition of your winch line is critical. A frayed synthetic rope or a corroded steel cable is a major liability. Answering “what size winch do I need?” is pointless if the rope itself is the weak link.

Here are a few practical tips to keep in mind:

- Inspect Before Every Use: This is non-negotiable. Before you even think about hooking up, give your line a once-over. On synthetic rope, look for flat spots, significant fraying, or any signs of melting from heat. For steel, run a gloved hand down the line to check for broken strands, kinks, and rust.

- Thicker Isn’t Always the Answer: A thicker rope obviously has a higher breaking strength, but it’s a trade-off. It reduces how much line you can fit on your winch drum. This is a big deal because your winch has maximum pulling power on the very first layer of rope closest to the drum. That power decreases with each additional wrap.

- Don’t Be Afraid to Replace It: Think of your winch rope as a wear item, like tires or brake pads. It’s not meant to last forever. Replacing it when it shows serious signs of wear is a small price to pay to ensure your winch can deliver its full, rated power when you need it most.

Industry Standards And Future-Proofing Your Investment

Smart buyers don’t just think about today’s trail ride; they plan for tomorrow’s challenges. When you’re trying to figure out what size winch you need, it pays to look beyond your own garage and see what the pros are doing. From construction sites to marine operations, professionals consistently choose capacity that gives them a significant buffer. They know that jobs evolve, and the winch they buy today has to handle the bigger loads of tomorrow. This forward-thinking approach is a lesson every off-roader should take to heart.

It’s a classic story in the 4×4 community: buying a winch that’s just big enough, only to realize six months later that it’s holding you back. Maybe you added a heavy-duty bumper, a rooftop tent, and a full-size spare tire. Suddenly, your vehicle’s weight has crept up by 500 pounds, and your once-adequate winch is now on the borderline. This common regret is why so many experienced operators say the same thing: “I wish I’d just bought the bigger one the first time.”

Planning for Future Growth

Future-proofing your investment means anticipating these changes. It’s not just about bolting on accessories; it’s about considering new adventures. Will you be exploring more challenging terrain a year from now? Will you be venturing out with friends who have heavier rigs you might need to recover?

Thinking bigger also means looking at where the industry is headed. The global winch market, which was projected to hit USD 1,625.6 million by 2025, sees huge demand from tough sectors like marine and oil & gas. In Europe, which accounts for over 30% of the market, safety standards and equipment capabilities are always advancing, pushing buyers toward more powerful and reliable options. You can see how these global winch market trends are evolving and get a sense of the direction things are moving.

To avoid buyer’s remorse, think about these points before you pull the trigger:

- Your Next Upgrade: Consider the gear you plan to add to your rig over the next one to two years. Factor that potential weight into your calculations now.

- Your Evolving Hobby: If you see yourself tackling tougher trails or joining group expeditions, you’ll want the capacity to handle more demanding recoveries for yourself and others.

- Technological Advances: Newer winches often come with improved motor efficiency and better gear ratios. A slightly larger, modern winch might offer better performance and longevity than a smaller one constantly pushed to its limits.

At the end of the day, the most expensive winch is often the one that’s too small for the job, because it forces you to buy a second one down the road. By investing a little more upfront in a higher-capacity model, you’re not just buying a piece of equipment; you’re buying peace of mind for all the adventures yet to come.

Costly Sizing Mistakes That Leave You Stranded

Learning from other people’s bad calls is a lot cheaper than making them yourself, especially when a poor choice can leave you stuck miles from civilization. The biggest mistake I see is simple: people underestimate the incredible forces involved in a recovery and buy a winch that’s just too small. It’s an easy way to save a few hundred bucks upfront, but it can backfire in spectacular fashion. You could be facing thousands in professional recovery fees or, even worse, a dangerous equipment failure on the trail.

The real question isn’t just “what size winch do I need for my truck?” It should be, “what size winch will get my truck out of the absolute worst spot I could possibly find myself in?”

I’ve heard the same story time and again from weekend adventurers. They buy an 8,000-pound winch for their 5,500-pound Jeep, thinking they’ve followed the 1.5x rule and are good to go. But once they add a heavy steel bumper, bigger tires, and get hopelessly bogged down in thick, suction-cup clay, that winch just screams, overheats, and dies. They learn the hard way that the most expensive winch is the one that’s too small for the job.

Recognizing You’ve Outgrown Your Winch

Sometimes, the winch you bought initially was fine, but your off-roading habits have evolved. If you’re noticing any of these red flags, it might be time to think about an upgrade:

- Your winch always seems to be struggling: If every single pull feels like a maximum-effort event where the motor is groaning and straining, you are constantly pushing the limits of its capacity. That’s a disaster waiting to happen.

- You’ve added significant weight: Did you recently install a rooftop tent, heavy-duty steel bumpers, rock sliders, or a full drawer system in the back? Your vehicle’s Gross Vehicle Weight (GVW) isn’t what it used to be, which means your original winch calculations are no longer valid.

- You’re tackling tougher trails: Those easy fire roads you started on are a distant memory. As you venture into more difficult terrain with steeper inclines, deeper mud, and more technical obstacles, your recovery needs become far more demanding.

Upgrading Without Breaking the Bank

If you’ve realized your current setup is no longer cutting it, don’t worry. A great way to offset the cost of a new, more powerful winch is to sell your smaller one. There’s a strong market for used winches, especially for folks with lighter vehicles like ATVs, side-by-sides, or smaller SUVs.

However, be cautious when considering buying a used winch yourself. You have no way of knowing its history—was it maintained? Was it ever overloaded? Internal damage can be invisible until the moment you need it most. When it comes to a piece of gear this critical for your safety, investing in a new, larger winch is almost always the smarter and safer long-term play. It’s not just about pulling power; it’s about buying priceless peace of mind.

Your Winch Sizing Action Plan

Alright, let’s put everything we’ve talked about into a straightforward plan you can use. Picking the right winch isn’t about crossing your fingers and hoping for the best; it’s a simple process of figuring out your real-world needs and applying a bit of practical math. With this approach, you can choose a winch that you know will have your back when you’re in a tough spot.

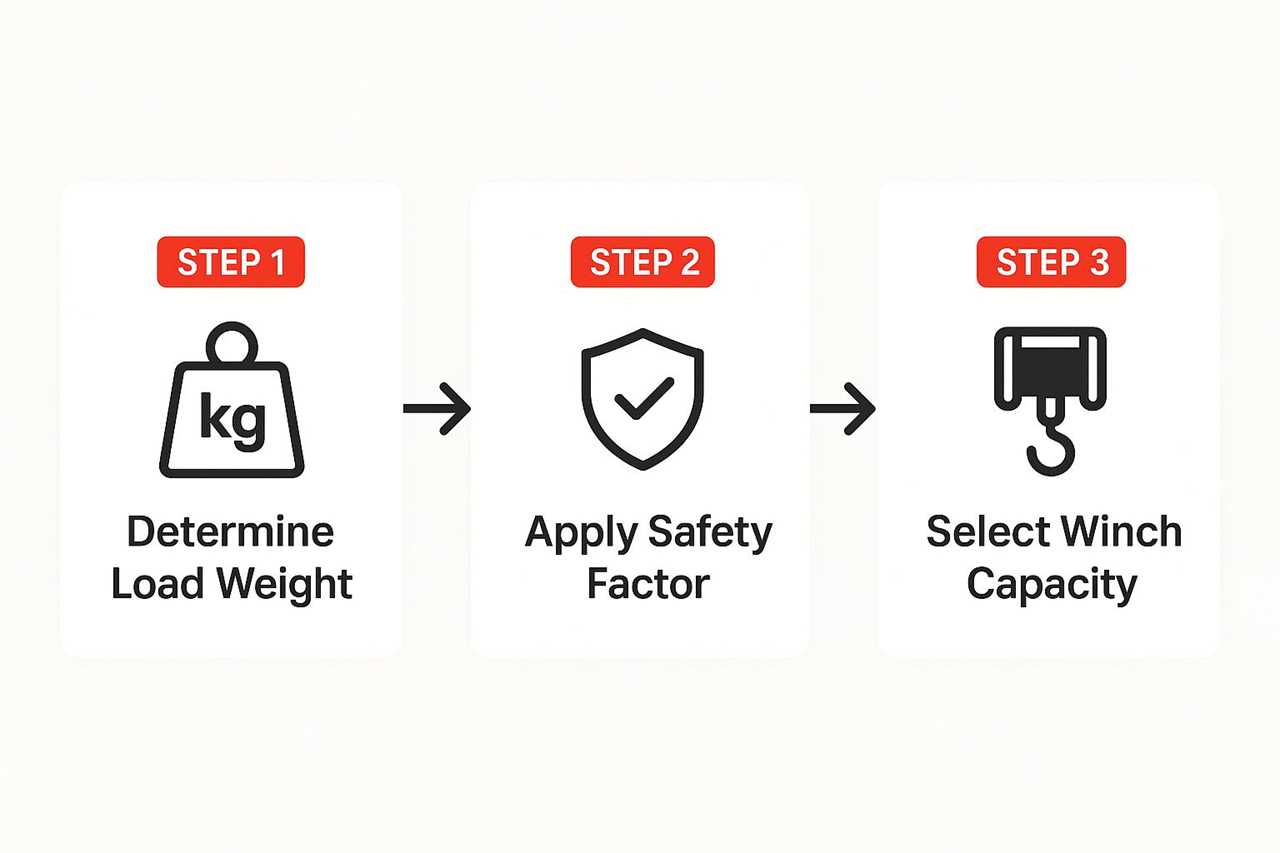

This infographic lays out the core decision-making process in three clear stages.

As you can see, it all starts with your vehicle’s weight. From there, you add a critical safety buffer to land on a capacity that’s right for you.

Calculating Your Minimum Capacity

Let’s run some actual numbers. The idea here is to find your Total Pulling Weight (TPW), which is the absolute bare-minimum capacity you should even think about.

The formula is pretty simple: Gross Vehicle Weight Rating (GVWR) x 1.5 = Minimum Winch Capacity.

You can find your rig’s GVWR on a sticker inside the driver’s side door jamb. For instance, if your truck has a GVWR of 6,000 pounds:

- 6,000 lbs (GVWR) x 1.5 (Safety Factor) = 9,000 lbs (Minimum Capacity)

This means a 9,000-pound winch is your starting point. Keep in mind, this calculation assumes you’re doing a straight-line pull on perfectly flat ground—a situation you’ll almost never encounter off-road. For a deeper dive, our complete guide on how to pick a winch for your 4×4 has even more details.

Prioritizing Your Needs

Now that you have your minimum capacity, it’s time to get honest about how you’ll actually use it. A quick self-check can help you decide if you need to aim higher than the baseline:

- Your Terrain: Are you often fighting through deep mud bogs, climbing steep, slick hills, or navigating rocky trails? If so, you need more pulling power. I’d recommend bumping up to a 2.0x safety factor for these conditions.

- Your Gear: Be realistic about the extra weight you carry. Heavy steel bumpers, a rooftop tent, and a full set of overland gear add up fast. If you’ve bolted on a lot of accessories, your factory GVWR is out the window, and a beefier winch is a must.

- Future Plans: Do you have dreams of tackling more difficult trails or longer, more remote trips in the future? Buying a winch with a little extra capacity now is much cheaper than having to buy a whole new one later.

Ultimately, figuring out what size winch you need is about being realistic about your adventures and preparing for the worst-case scenario. When you have the right gear for any situation, every off-road trip becomes safer and way more fun. You can find all the equipment and expert advice you need over at Offroading.com.

https://offroading.com/what-size-winch-do-i-need/?utm_source=rss&utm_medium=rss&utm_campaign=what-size-winch-do-i-need

Backyard GrillingWeekend WarriorsAdvice from DadBeard GroomingTV Shows for Guys4x4 Off-Road CarsMens FashionSports NewsAncient Archeology World NewsPrivacy PolicyTerms And Conditions

Backyard GrillingWeekend WarriorsAdvice from DadBeard GroomingTV Shows for Guys4x4 Off-Road CarsMens FashionSports NewsAncient Archeology World NewsPrivacy PolicyTerms And Conditions