When you’re deciding between synthetic winch rope vs steel, it’s a classic matchup. You are comparing modern material science against old-school brute strength. Synthetic ropes are light, flexible, and safer if they snap. Steel cables are workhorses, incredibly tough against abrasion and heat.

The right choice depends on where you’ll be wheeling and your safety priorities. What you’re recovering also plays a significant role. Let’s break down the key differences to help you decide.

Understanding the Core Differences

Picking the right winch line is a huge deal for safe and effective recovery. This isn’t just a simple “new vs. old” debate. It’s about matching the right tool to the job.

The arrival of synthetic ropes, made from materials like Dyema, changed the game. They offer incredible strength but are up to 80% lighter than steel. This weight difference makes them easier and safer to handle on the trail.

To really get a feel for it, let’s put them head-to-head. For a deeper dive, check our guide on choosing between wire cable and synthetic rope.

Quick Look: Synthetic Rope vs Steel Cable

Here’s a quick rundown of how these two winch lines compare. This is a great starting point for figuring out which one fits your needs.

| Attribute |

Synthetic Winch Rope |

Steel Winch Cable |

| Material |

High-Modulus Polyethylene (HMPE) |

Braided Galvanized Steel Wire |

| Weight |

Extremely Lightweight |

Very Heavy |

| Safety on Break |

Falls to the ground with low energy |

Whips back violently (high risk) |

| Handling |

Flexible, easy to handle, no burrs |

Stiff, prone to kinking and burrs |

| Abrasion Resistance |

Vulnerable to sharp edges and rocks |

Highly resistant to abrasion |

| Maintenance |

Requires cleaning, UV/heat protection |

Needs lubrication to prevent rust |

This table shows there’s no single “best” option for everyone. It’s all about context and how you use your equipment.

The key takeaway is that neither one is always better. A steel cable is perfect for dragging logs across a rocky field. A synthetic rope is almost always the safer and more practical pick for a muddy trail recovery.

When to Choose a Traditional Steel Winch Cable

Even with the buzz around synthetic ropes, don’t count out steel winch cable. In certain nasty, demanding environments, it’s still the undisputed king. For logging or heavy construction, its raw toughness is exactly what’s needed.

The durability of steel makes it the go-to when your line is constantly dragged over sharp rocks. It stands up to stumps or other abrasive junk on the ground. This makes it a reliable choice for the toughest jobs.

This ability to take a beating is a huge deal. This is especially true when friction and heat are part of the job. A steel cable can handle high temperatures from a long pull without losing integrity.

Durability Under Pressure

Steel’s resistance to cuts and abrasion is what makes it so tough. Synthetic ropes are strong but vulnerable to nicks from sharp objects. Steel just shrugs off the kind of abuse that would shred a synthetic rope.

Of course, you’ve got to take care of it if you want it to last. Regular checks for broken strands and some lubricant will keep rust away. Keeping it clean and dry after a pull is the best way to fight corrosion.

“A key disadvantage of steel cables is their susceptibility to rust if not properly maintained, weakening the cable over time and increasing failure risk. The cost efficiency of steel cables—often 20-30% cheaper than synthetic alternatives—along with durability in abrasive environments, sustains their market dominance.”

That cost-effectiveness, combined with its rugged nature, is why steel cable remains a major player. For more information, explore the comparison between steel and synthetic ropes on news.superwinch.com.

Why Synthetic Winch Ropes Are Gaining Popularity

If you’ve been around the off-road scene, you’ve noticed the shift away from steel. This move toward synthetic winch ropes is a smart evolution. It’s driven by serious performance upgrades.

The biggest advantage is the incredible strength-to-weight ratio. These lines are often up to 80% lighter than steel. That huge difference matters when managing a recovery on a steep, muddy hill.

This weight reduction makes the winching process faster and less exhausting. But convenience isn’t the main story here—safety is. Steel cables store a terrifying amount of kinetic energy and whip back with deadly force if they snap.

Safety and Practical Field Use

When you compare synthetic winch rope vs steel on safety, it’s not a fair fight. Synthetic is the hands-down winner. If a synthetic line breaks, its low mass means it just drops to the ground.

This single characteristic drastically cuts down the risk of serious injury. To learn more, see what Equipment World has to say about synthetic winch lines.

On top of that, synthetic ropes are much more flexible and way easier on your hands. You’ll never have to worry about the painful steel burrs that plague old cables. This flexibility also prevents kinking and makes spooling it back onto the winch drum a breeze.

Another benefit is that you can repair them in the field. A snapped synthetic rope can often be braided back together for a temporary fix. This combination of safety and practicality explains why so many off-roaders are making the switch.

Comparing Strength, Weight, and Safety in Practice

https://www.youtube.com/embed/imJuNlAE3fQ

When you put synthetic winch rope vs steel to a real-world test, the differences become clear. They might have similar load ratings, but how they handle that load is a different story. Synthetic rope has an elasticity that helps it absorb shock loads.

Steel, on the other hand, is completely unforgiving. Every bit of jarring force is transferred straight to your vehicle’s frame. You feel it, and your rig feels it.

The weight difference is something you’ll notice immediately. A synthetic line can be up to 80% lighter than its steel counterpart. This isn’t just about reducing the load on your front suspension.

It’s about practical handling. Lugging a heavy, greasy steel cable up a slippery hill is exhausting. It adds a layer of risk you don’t need in a tough spot.

The Decisive Factor: Safety

This is where the debate often ends for many off-roaders. A steel cable under tension stores a tremendous amount of kinetic energy. If it snaps, it whips back with enough force to be lethal.

Synthetic rope stores far less energy due to its low mass. In the rare event of a failure, it tends to just fall to the ground. For many, this one characteristic is the deciding factor.

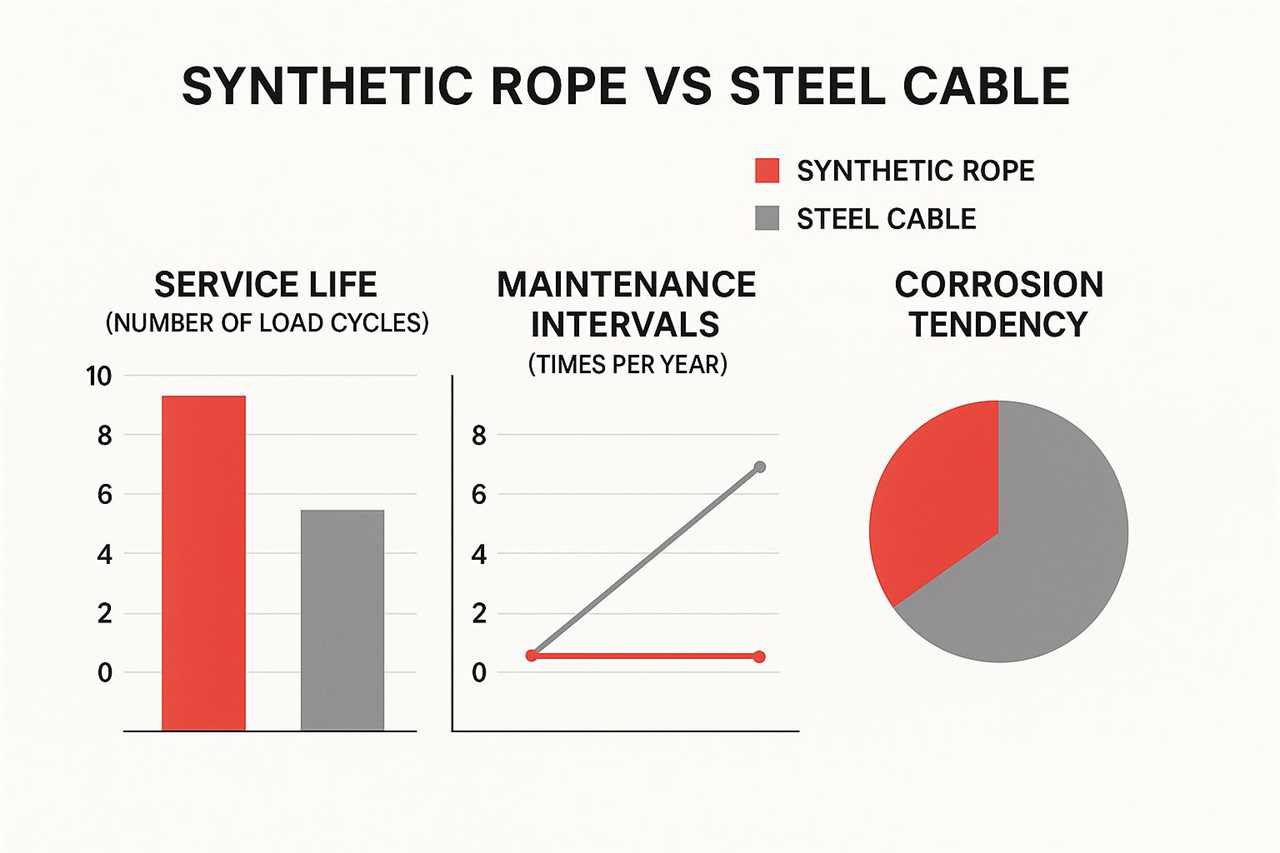

The image below gives a great visual breakdown of how these materials stack up. It looks at service life, maintenance, and their ability to resist the elements.

As you can see, steel’s vulnerability to rust and corrosion is a major drawback. This directly impacts its reliability and the amount of upkeep it needs.

In-Depth Feature Comparison: Winch Line Materials

Let’s break down the head-to-head matchup. Here is a detailed look at the characteristics that matter most when you’re stuck.

| Characteristic |

Synthetic Rope (HMPE) |

Steel Cable |

| Handling |

Lightweight, flexible, and easy to carry. No sharp burrs. |

Heavy, stiff, and prone to “jaggers” (broken wire strands). |

| Energy Storage |

Low. Drops to the ground if it fails. |

High. Whips back with dangerous force if it snaps. |

| Abrasion Resistance |

Vulnerable to sharp rocks and heat. Requires a chafe guard. |

Excellent. Highly resistant to abrasion and direct heat. |

| UV Degradation |

Susceptible over time. Best stored with a winch cover. |

Not affected by UV light. |

| Water Absorption |

Can absorb water, which may freeze in cold climates. |

Does not absorb water. |

| Maintenance |

Needs occasional rinsing to remove dirt and grit. |

Requires regular oiling to prevent rust and corrosion. |

| Cost |

Higher initial investment. |

More affordable upfront. |

This table highlights the give-and-take. While steel wins on raw abrasion resistance, synthetic rope dominates in safety and ease of use. For more hands-on advice, see our guide on how to properly use a winch.

Maintenance and Durability Across Different Terrains

In the synthetic winch rope vs steel debate, long-term performance comes down to maintenance. Each material has its own weakness. You need to know what you’re up against to keep your line in top shape.

The terrain you’re in also throws unique challenges that can wreck a winch line. For old-school steel cable, the number one enemy is rust.

Any time you get it muddy or wet, you must clean and re-lube the cable. This prevents corrosion between the wire strands. Corrosion can rot the cable’s strength from the inside out.

Protecting Your Investment

With synthetic rope, you’re fighting a different battle. Its three main vulnerabilities are abrasion, UV damage, and heat. Unlike steel, synthetic rope gets chewed up by sharp rocks or burrs.

Using a protective chafe guard during pulls is non-negotiable. After a muddy recovery, always unspool your synthetic rope. Give it a good rinse with plain water.

All that embedded sand and grit acts just like sandpaper. It grinds away at the rope’s fibers every time you spool it in and out. The sun also degrades the fibers, slowly sapping the rope’s strength. The easiest defense here is a simple winch cover.

A little bit of care goes a long way. It ensures your synthetic line is ready to perform when you’re in a bind.

Making the Right Choice for Your Winch

So, how do you pick the right winch line? Be honest about your needs and the terrain you tackle. Also, consider how much you prioritize safety.

There isn’t a single “best” option here. Choose the one that makes the most sense for how you’ll use your winch. For most weekend trail riders, synthetic winch rope is the way to go.

It’s lightweight, making recoveries less of a workout. More importantly, its safer failure mode brings peace of mind. This is especially true when friends or family are helping.

Situational Recommendations

On the flip side, if you’re doing heavy industrial work, a steel cable is still king. Its resistance to cuts and heat gives it an unmatched lifespan in harsh situations. If your line is constantly abused on unforgiving surfaces, steel is the reliable workhorse you need.

Beyond your main use case, don’t forget these other critical factors:

- Your Budget: Steel cable is cheaper upfront, making it a solid, budget-friendly choice.

- Frequency of Use: If you winch often, the easier handling of synthetic might be worth the extra cost.

- Fairlead Compatibility: You need a smooth hawse fairlead for synthetic rope or a roller fairlead for steel to avoid damage.

The global wire rope market was valued at around $14 billion in 2023. Synthetic ropes are projected to grab the largest market share. This is thanks to the boom in off-road vehicle sales and industrial demand.

For a really deep dive into this whole debate, check out our complete synthetic winch rope vs steel cable guide.

At Offroading.com, our goal is to provide the expert guides and tutorials you need to tackle any terrain with confidence. Explore our extensive resources to make every off-road adventure a safe one. Discover more at https://www.offroading.com.

https://offroading.com/synthetic-winch-rope-vs-steel/?utm_source=rss&utm_medium=rss&utm_campaign=synthetic-winch-rope-vs-steel

Backyard GrillingWeekend WarriorsAdvice from DadBeard GroomingTV Shows for Guys4x4 Off-Road CarsMens FashionSports NewsAncient Archeology World NewsPrivacy PolicyTerms And Conditions

Backyard GrillingWeekend WarriorsAdvice from DadBeard GroomingTV Shows for Guys4x4 Off-Road CarsMens FashionSports NewsAncient Archeology World NewsPrivacy PolicyTerms And Conditions