Let’s settle the debate once and for all: recovery straps are built to stretch, while tow straps are built for static pulling. Using the wrong one is a shortcut to serious vehicle damage or catastrophic equipment failure. This single difference is everything, and it dictates their specific, non-interchangeable jobs.

Stuck vs. Hauling: Understanding the Core Difference

When you’re staring at these two pieces of gear, your choice comes down to one simple question: Is the vehicle completely immobilized, or is it free-wheeling? The answer tells you exactly which tool to grab.

Think of a recovery strap as a massive, powerful rubber band. It’s designed specifically for yanking a vehicle that’s hopelessly stuck in mud, sand, or deep snow. A tow strap, on the other hand, is basically a heavy-duty, rigid chain for the simple task of pulling a disabled but rolling vehicle on a flat, stable surface.

Elasticity: The Critical Safety Differentiator

The real magic—and the danger—is in the materials. A recovery strap is made from nylon, which gives it an incredible stretch of around 15–20%. This elasticity is what allows it to store and release kinetic energy for those dynamic ‘snatch’ recoveries.

Tow straps are almost always made from polyester, which has very little give—only about 3–5% stretch. That minimal flex means it’s perfect for a steady, controlled pull without any bouncing. You can find more details about strap materials over at Dawnerz.com.

Key Takeaway: Never, ever use a tow strap for a kinetic or ‘snatch’ recovery. Its lack of stretch will transfer a violent, instantaneous shock directly to your vehicle’s frame. This can easily rip off attachment points or even bend the chassis.

To make the choice crystal clear, let’s break down their main characteristics side-by-side.

Recovery vs Tow Strap At a Glance

Here’s a quick cheat sheet to help you grab the right strap every time. This table sums up the most important differences for a fast, informed decision when you’re out on the trail or roadside.

| Characteristic |

Recovery Strap (Kinetic) |

Tow Strap (Static) |

| Primary Material |

Nylon |

Polyester |

| Stretch Capacity |

High (15-20%) |

Very Low (3-5%) |

| Primary Use |

Freeing a stuck vehicle |

Towing a rolling vehicle |

| Force Type |

Dynamic (Kinetic Energy) |

Static (Steady Pull) |

| End Fittings |

Reinforced looped ends |

Often has metal hooks |

Ultimately, a kinetic recovery strap is your go-to for getting unstuck, while a static tow strap is for simple hauling. Mixing them up isn’t just a bad idea—it’s dangerous.

How Material and Construction Define Function

The real difference between a recovery strap and a tow strap isn’t just a name game; it’s literally woven into their DNA. The choice of material and how they’re put together is completely purpose-driven, dictating exactly how—and when—you can safely use each one. Think of it this way: one is engineered to be a massive, powerful spring, while the other is meant to be as rigid as a steel chain.

It all comes down to the specific synthetic fibers they use. Get a handle on these materials, and you’ll immediately see why you can never swap one for the other.

The Power of Nylon in Recovery Straps

Recovery straps are made from nylon, a material specifically chosen for its impressive elasticity. This isn’t just some minor detail; it’s the heart of how they work. A quality nylon strap is designed to stretch—a lot. We’re talking somewhere between 15% and 20% of its total length when under a heavy load.

Picture it like a giant rubber band for your truck. As the recovery vehicle drives forward, the nylon stretches out, storing up a huge amount of kinetic energy. Once it hits its max stretch, it snaps back with a powerful but controlled “pop.” This action yanks the stuck vehicle free without the kind of violent, damaging shock that breaks things. It’s this smooth transfer of energy that makes a “snatch” recovery so effective and much safer for your vehicle’s frame.

Polyester: The Foundation of Tow Straps

On the flip side, you have tow straps, which are almost always made of polyester. This material is picked for the exact opposite reason: it has almost no stretch. A typical polyester tow strap will only elongate by a mere 3% to 5%. This creates a predictable and stiff link between two vehicles.

That lack of give is completely by design. When you’re towing a disabled (but still rolling) vehicle on a road, the last thing you want is any slack or bouncing. The polyester build gives you a steady, constant pull, preventing the dangerous jerking that would happen if you tried to tow with a stretchy nylon strap. Using a proper tow strap feels more like having a solid tow bar connecting the vehicles, giving you control and stability.

Critical Insight: That stretch in a nylon recovery strap is a crucial safety feature. It acts as a shock absorber for the immense forces of a dynamic pull, protecting your rig’s attachment points and frame from a sudden jolt that could otherwise cause catastrophic failure.

Construction Details That Matter

Beyond the basic material, you’ll notice small construction details that reinforce what each strap is built for. These are the things that directly impact how durable, safe, and effective a strap is out in the field.

- Reinforced Eyelets: Recovery straps have big, heavily stitched nylon loops, or “soft eyes.” They’re designed to be used with proper shackles and are far less likely to become lethal projectiles if a metal component fails.

- Stitching Patterns: Look closely at the stitching. On both types of straps, this is a critical component of its overall strength. You’ll see robust, often redundant stitching patterns that ensure the webbing and loops can handle loads way beyond the vehicle’s weight.

- Protective Coatings: A lot of good straps come with special coatings that resist UV rays and abrasion. This is a bigger deal than you might think, as sunlight and rough, rocky terrain can degrade the fibers over time, seriously compromising the strap’s strength.

Decoding Strength Ratings and Load Capacity

When you’re out on the trail, the numbers stamped on a recovery strap aren’t just suggestions—they’re the hard limits that keep you and your rig safe. Getting this wrong when comparing a recovery strap vs a tow strap can lead to catastrophic failure, turning a piece of essential gear into a dangerous projectile. It’s a mistake you only make once.

The two biggest numbers you’ll see are the Minimum Breaking Strength (MBS) and the Working Load Limit (WLL). They sound similar, but they tell you two very different things about what your strap can handle.

Minimum Breaking Strength vs Working Load Limit

Minimum Breaking Strength (MBS) is exactly what it sounds like: the absolute maximum force a strap can take in a lab before it snaps. This is its ultimate failure point under perfect conditions. You should never, ever get close to this number in a real-world recovery because it offers zero safety margin.

The Working Load Limit (WLL), on the other hand, is the number that actually matters for real-world use. It’s the maximum force the strap is designed to handle repeatedly and safely. Manufacturers calculate the WLL by taking the MBS and dividing it by a safety factor, which is usually somewhere between 3:1 and 5:1. This is your true operational ceiling.

Crucial Rule of Thumb: Always pick your strap based on its WLL, not its MBS. The WLL is the manufacturer’s official stamp of approval for safe use, and it already has that critical safety buffer baked right in.

Calculating Your Needs: The 3X Rule

A widely accepted rule in the off-roading community is to choose a strap with a Minimum Breaking Strength (MBS) at least three times the Gross Vehicle Weight (GVW) of the lighter of the two vehicles. This isn’t overkill. The 3X rule is designed to account for the incredible dynamic forces that build up during a real recovery, which can spike far beyond the vehicle’s simple static weight.

Let’s say your SUV has a GVW of 6,000 pounds. You’ll need a recovery strap with an MBS of at least 18,000 pounds. Remember, you’re not just pulling the vehicle’s weight; you’re fighting against the immense resistance from being bogged down in deep mud, sand, or snow. A tow strap for the same vehicle would have a much lower requirement since it’s only dealing with rolling resistance on a hard surface.

You can see this principle at play in the market. Most common 3″ x 20′ straps built for 4x4s and trucks boast break strengths over 31,000 pounds. For bigger rigs and tougher recoveries, you’ll find straps rated well past 40,000 pounds. If you want to dive deeper, you can learn more about how manufacturers rate their recovery straps to get a better feel for these numbers.

Choosing an underrated strap for your vehicle is one of the most dangerous mistakes you can make out on the trail. The forces in a recovery can easily skyrocket past a vehicle’s curb weight. An undersized strap will snap, and when it does, it creates a life-threatening situation. Always play it safe and pick a strap that is comfortably oversized for your needs.

When to Use a Recovery Strap vs. a Tow Strap

Knowing the difference between these straps is one thing, but knowing exactly which one to grab when you’re in a tough spot is what really matters out on the trail. The whole recovery strap vs. tow strap debate boils down to one simple question: is the vehicle stuck against something, or is it just broken down but can roll freely?

Your answer tells you whether you need the dynamic energy of a recovery strap or the static control of a tow strap.

A recovery strap is what you need for a dynamic situation. This is for when a vehicle is genuinely stuck—we’re talking buried up to the axles in mud, high-centered on a big rock, or bogged down in deep sand or snow. In these moments, the vehicle can’t move on its own because something is physically holding it back.

This is where the nylon construction of a recovery strap shines. It’s designed to stretch and store kinetic energy, creating a powerful “snatching” effect. This applies a steadily increasing force that pops the vehicle free without the kind of damaging, sudden jolt you’d get from a chain or a non-stretchy strap. For a much deeper dive into this technique, our guide on snatch straps has all the details you’ll need.

The Right Job for a Tow Strap

On the flip side, a tow strap is built for simple, low-stress static situations. Its job is to pull a vehicle that’s disabled but can still roll on its own wheels. Think of a car with a dead engine on the highway or a truck that won’t start in a flat parking lot.

Because a tow strap is made from low-stretch polyester, it acts more like a rigid link between the two vehicles. This is exactly what you want for maintaining control and preventing the dangerous slack-and-jerk motion that a stretchy recovery strap would create on pavement. You have to get all the slack out of a tow strap before you start pulling to keep the tow smooth and predictable.

Critical Warning: Never, ever use a tow strap for a dynamic recovery. Its lack of stretch will send a catastrophic shockwave right through the vehicle’s frame and attachment points. This can easily shear off recovery points or bend a chassis, causing thousands in damage and creating an incredibly dangerous, potentially lethal, situation.

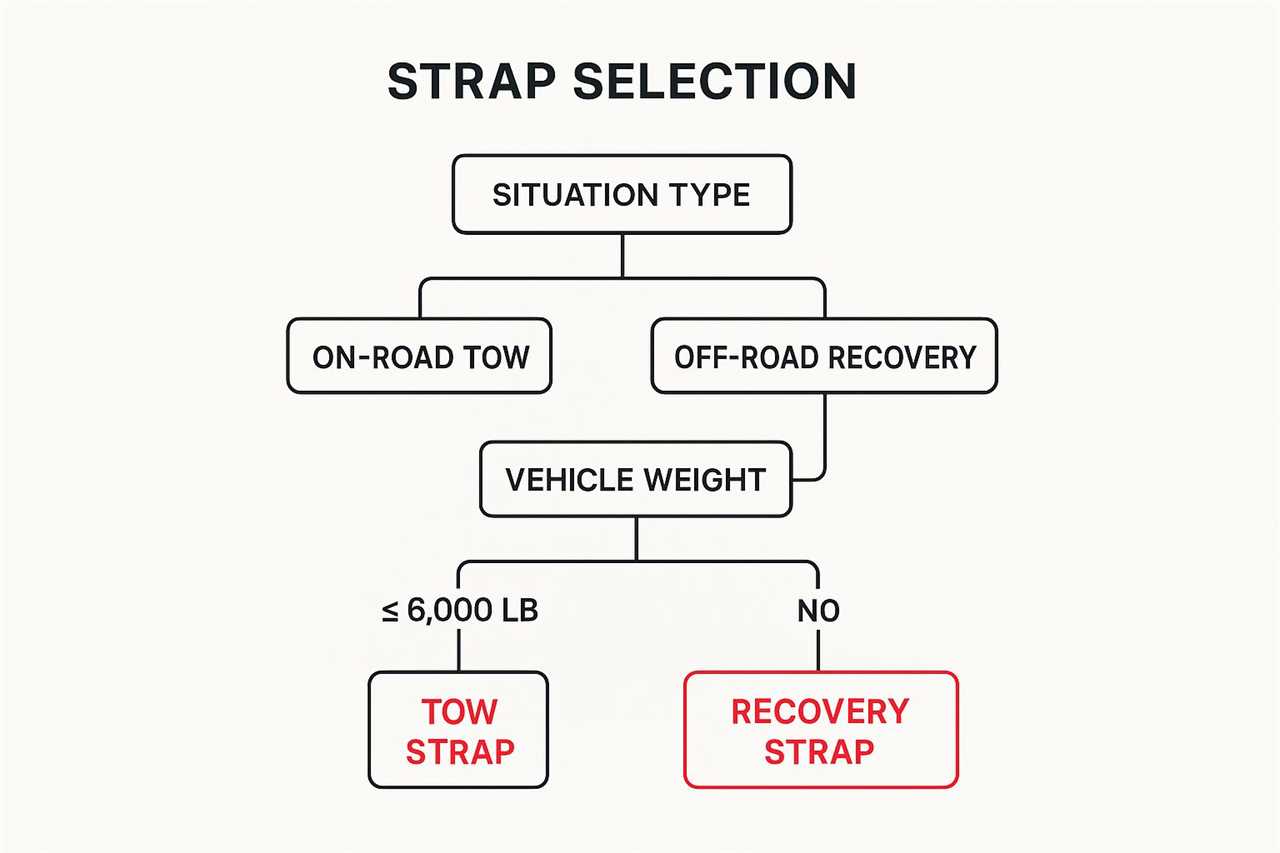

This decision tree gives you a quick visual guide, walking you from the type of situation you’re in to the right strap for the job.

As you can see, if you’re off-road and dealing with high resistance, you need a recovery strap. If you’re on-road and the vehicle can roll freely, you need a tow strap. It’s that simple.

Essential Safety Procedures and Common Mistakes

Knowing the difference between a recovery strap and a tow strap is one thing, but it’s useless if you don’t master the safety rules. The forces involved in pulling a stuck vehicle are no joke—one small mistake can lead to busted equipment, serious vehicle damage, or even life-threatening injuries. Following a strict safety checklist isn’t optional; it’s something you have to do every single time you rig up.

It all starts with your connection points. You must always attach straps to rated recovery points that are bolted or welded directly to your vehicle’s frame. These points are built to handle the insane shock loads of a real-world recovery. Never, and I mean ever, hook a strap to a shipping tie-down loop or, even worse, a trailer tow ball. A tow ball is only designed for downward pressure, not the sideways shear force of a recovery. They snap off easily and turn into deadly metal cannonballs.

Connecting Your Gear Correctly

Where you connect your strap is critical, but how you connect it matters just as much. Metal D-ring shackles have been the standard for years, but a lot of seasoned off-roaders are now switching to soft shackles. These are made from ridiculously strong synthetic rope, making them tough but also incredibly lightweight. If a soft shackle fails, it just drops to the ground. If a metal shackle breaks, it can fly through the air with enough force to be lethal.

Another piece of gear that’s absolutely non-negotiable is a winch line damper (or a heavy recovery blanket). Just drape it over the middle of the strap once it’s under tension. If the strap snaps, the damper’s weight will absorb the kinetic energy and force the broken ends straight down, preventing that horrifying “slingshot” effect. It’s a simple step that can turn a potential catastrophe into a minor headache.

Critical Safety Insight: The “danger zone” is a huge area—think 1.5 times the length of your tensioned strap in every direction. Nobody should be standing inside this zone during a pull. Keep spectators far away, and make sure the communication between drivers is constant and crystal clear.

Do’s and Don’ts for Safe Recovery

To help these life-saving rules stick, here’s a quick rundown. Memorizing this list can help you avoid the most common and dangerous mistakes people make out on the trail.

Recovery Do’s:

- DO check all your gear for cuts, frays, or damaged stitching before every single use. If it looks worn out, toss it.

- DO use a winch line damper or recovery blanket on every pull. No exceptions.

- DO make sure all bystanders are way outside the danger zone.

- DO agree on clear hand signals between drivers before you start.

Recovery Don’ts:

- DON’T ever hook a strap to a tow ball, axle, or suspension part.

- DON’T connect two straps together with a metal shackle. This just creates a new projectile point if something fails.

- DON’T start a recovery without a solid plan and clear communication.

- DON’T use a strap that isn’t rated for your vehicle’s weight.

These rules apply whether you’re using a simple recovery strap or a more complicated setup. If you’re getting into more advanced recoveries, check out our detailed guide on how to use a winch for more safety tips.

Your Guide to Choosing the Right Strap

Alright, let’s get down to it. Picking between a recovery strap and a tow strap isn’t about what looks toughest on your rig; it’s about making an honest call on how you actually use your vehicle. The right choice is the one that matches your reality, keeps you safe, and gets you home without a bigger headache.

To cut through the noise, just ask yourself a few straight-up questions. This isn’t complicated. A quick personal checklist will point you right to the tool you actually need and make sure you’re spending your money wisely.

Your Personal Buying Checklist

- What does my rig really weigh? Don’t guess. Look for the Gross Vehicle Weight (GVW) on the sticker in your door jamb, not just the curb weight. For recovery straps, you have to follow the 3X rule: the strap’s minimum breaking strength needs to be at least three times your vehicle’s GVW. No exceptions.

- Where am I realistically driving? If you’re the type who lives for getting stuck in mud, sand, or on rocky trails, a nylon recovery strap isn’t just a good idea—it’s essential. But if you spend 99% of your time on pavement, a simple polyester tow strap for roadside emergencies is the more practical and affordable pick.

- What’s my budget? A high-quality recovery strap is going to cost more, but think of it as an investment in your safety if you’re hitting the trail. A tow strap is much cheaper and is perfectly fine for basic hauling on hard surfaces.

Expert Insight: Don’t just buy a strap; build a recovery system. A strap by itself is only one piece of the puzzle. To do this right, you need to invest in quality shackles, a winch line damper, and a good pair of gloves. That’s what makes a complete—and safe—solution.

When to Retire Your Gear

Even the toughest gear has a lifespan. Your safety, and the safety of those around you, depends on knowing when a strap is done. Give your equipment a good look-over before every trip. If you see any of these deal-breakers, it’s time to retire it.

- Fuzzy or frayed fibers, which is a dead giveaway of internal abrasion and a serious loss of strength.

- Any cuts, nicks, or burn marks anywhere on the webbing.

- Stitching that’s pulled or damaged, especially around the reinforced loops on the ends.

If you spot any of these signs, that strap is compromised. Don’t risk it. Using damaged gear is a gamble you will eventually lose. Toss it and get a new one. To get a fresh start, you might consider one of the best off-road recovery kit options, which usually bundles new straps with other must-have accessories.

Common Questions Answered

Even after getting the main differences down, a few specific questions always pop up. We hear them all the time from folks just getting into off-roading or those wanting to make sure they’re using their gear right. Let’s clear up some of the most common ones.

Can I Use a Recovery Strap for Flat Towing?

Absolutely not. Trying this is a recipe for disaster. That signature stretchiness in a recovery strap is great for a dynamic “snatch” recovery, but it creates a dangerous bungee cord effect when you’re trying to tow a free-wheeling vehicle on the road.

This constant jerking and slackening puts incredible shock loads on the frames and drivetrains of both vehicles. It also makes controlling the vehicle being towed next to impossible. For any kind of on-road towing, you must use a static, no-stretch tow strap. No exceptions.

What Exactly Are Rated Recovery Points?

These are the real deal. Rated recovery points are specially designed connection points—usually beefy hooks or closed-loop D-ring mounts—that are bolted or welded directly to your vehicle’s frame. They’re engineered from the ground up to handle the massive forces of a recovery without breaking a sweat.

Crucial Distinction: Don’t ever confuse these with the flimsy tie-down hooks you see on many stock vehicles. Those are only there to secure a car to a trailer for transport. Using a tie-down hook for recovery is asking for it to snap off and turn into a lethal metal projectile.

How Should I Clean and Store My Straps?

Taking care of your gear is non-negotiable if you want it to last. After a day out, especially if you’ve been in mud or sand, give your straps a good rinse with plain water. If they’re really caked in grime, a bit of mild detergent is okay, but never hit them with a pressure washer. That just forces sand and grit deeper into the fibers, which will tear them apart from the inside out.

Once clean, let the strap air dry completely, but keep it out of direct sunlight. Finally, store it in a cool, dry place, preferably in a dedicated gear bag. This keeps mildew at bay and protects the nylon or polyester from breaking down due to UV exposure.

https://offroading.com/recovery-strap-vs-tow-strap/?utm_source=rss&utm_medium=rss&utm_campaign=recovery-strap-vs-tow-strap

Backyard GrillingWeekend WarriorsAdvice from DadBeard GroomingTV Shows for Guys4x4 Off-Road CarsMens FashionSports NewsAncient Archeology World NewsPrivacy PolicyTerms And Conditions

Backyard GrillingWeekend WarriorsAdvice from DadBeard GroomingTV Shows for Guys4x4 Off-Road CarsMens FashionSports NewsAncient Archeology World NewsPrivacy PolicyTerms And Conditions